Sustainable Packaging Coalition and Center for the Circular Economy at Closed Loop Partners Announce Winner of the FlexPack Recovery Challenge

Start-ups from across the globe showcased their recovery technologies for a fast-growing category of hard-to-recycle flexible plastic packaging, and one winner was selected to join a mentorship program with the Sustainable Packaging Coalition & Closed Loop Partners.

CHARLOTTESVILLE, VA and NEW YORK, NY — the Center for the Circular Economy at Closed Loop Partners and the Sustainable Packaging Coalition (SPC) have announced the winner of the FlexPack Recovery Challenge: ReNew ELP.

In October 2018, the SPC and the Center for the Circular Economy at Closed Loop Partners launched the FlexPack Recovery Challenge, an open competition for innovators, entrepreneurs, and start-ups to submit new ideas for reprocessing technologies capable of beneficially recovering multi-material flexible packaging waste.

Five finalists were selected by a panel of judges from the SPC and the Center for the Circular Economy at Closed Loop Partners staff, as well as with input from industry advisors. Each finalist participated in the SPC’s spring conference SPC Impact and presented to an audience of major brands, plastic manufacturers, and packaging suppliers, including members of the SPC’s Industry Leadership Committee on Multi-Material Flexible Recovery, on how their technologies can beneficially recover the embodied environmental investment within multi-material flexible packaging waste and can be scaled to provide meaningful solutions. These finalists included Cadel De-Inking, ReNewELP, Renewlogy, Synova-BioBTX, and Ekopolimer. Read more about all of our finalists.

Among the five finalists, ReNewELP was selected as the final Challenge winner. RenewELP will receive a free year of membership to the SPC and enter into a mentorship program jointly run by the SPC and Closed Loop Partners.

“RenewELP submitted a detailed, transparent process description and market analysis. We were impressed with the processing capacity scale (up to 80,000 -100,000 tons per year in their initial facility) and the fact that their unique CAT-HTR technology allows for mixed waste feedstocks, including paper, PET and organics. Their modular approach considers variable material costs in different markets and their end markets for diverse hydrocarbon products like oils, waxes, and chemicals represent large market potential. RenewELP is a great fit to participate in a mentorship program run by our organizations,”

said representatives from the SPC and Closed Loop Partners in a joint statement.

The SPC & The Center for the Circular Economy at Closed Loop Partners team followed up with Richard Daley, Managing Director of RenewELP, for a post challenge interview.

Read the Q&A with Richard here

The SPC and CLP believe that all of technologies presented by the Finalists represent the kinds of diverse solutions needed for recovery of flexible packaging. We look forward to staying in touch with all the finalists and tracking and promoting their progress.

Learn more about the FlexPack Recovery Challenge.

ABOUT THE CENTER FOR THE CIRCULAR ECONOMY AT CLOSED LOOP PARTNERS

The Center for the Circular Economy brings together industry experts, academic researchers, and entrepreneurs who are solving for today’s most pressing challenges in design and reuse, providing a collaboration center for innovators to commercialize products, services and technologies that are leading the transition from a linear take, make, waste economy to a restorative one in which materials are shared, re-used, and continuously cycled.

ABOUT THE SUSTAINABLE PACKAGING COALITION

The Sustainable Packaging Coalition is a membership-based collaborative led by an independent non-profit that believes in the power of industry to make packaging more sustainable. Using an objective life-cycle-based approach, we work in a constructive atmosphere to provide thought leadership and bring our members together to strengthen and advocate the business case for more sustainable packaging.

Related posts

Press Release

The Petaluma Reusable Cup Project: Starbucks, The Coca-Cola...

The collaboration, led by the NextGen Consortium, makes...

Press Release

Does Compostable Packaging Actually Break Down? Composting...

Data in new report reveals that certified food-contact...

Press Release

First-of-Its-Kind Study by the Composting Consortium...

Commonly held assumptions about contamination were...

Press Release

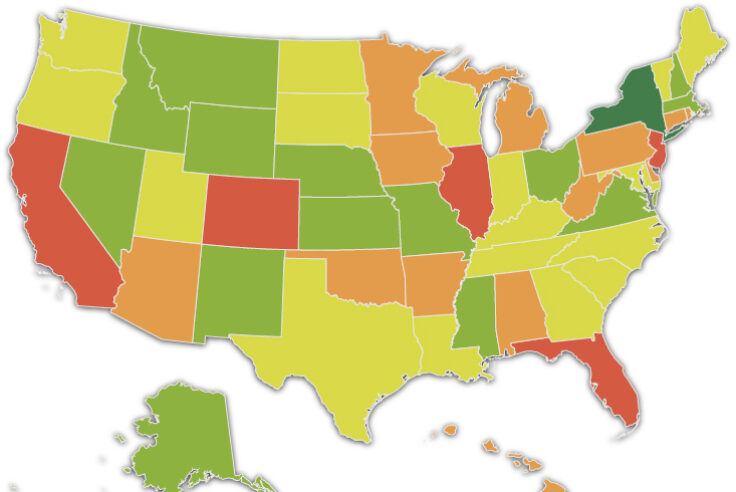

Closed Loop Partners and the U.S. Plastics Pact Release...

Key findings support the development of more effective...

Blog Post

What Brands Need to Know to Increase the Recovery of...

Permitting for composting facilities is complex, but...

Press Release

New Report from the NextGen Consortium Shares Path...

Insights include solutions for paper mills, material...

Reuse

Blog Post

When Reusable Cups Reach End-of-Life: 5 Tips to Ensure...

The NextGen Consortium shares 5 tips to ensure reusable...

Blog Post

How a South Carolina Paper Mill Started Recycling Your...

In July 2022, Sonoco announced it would accept paper...

Press Release

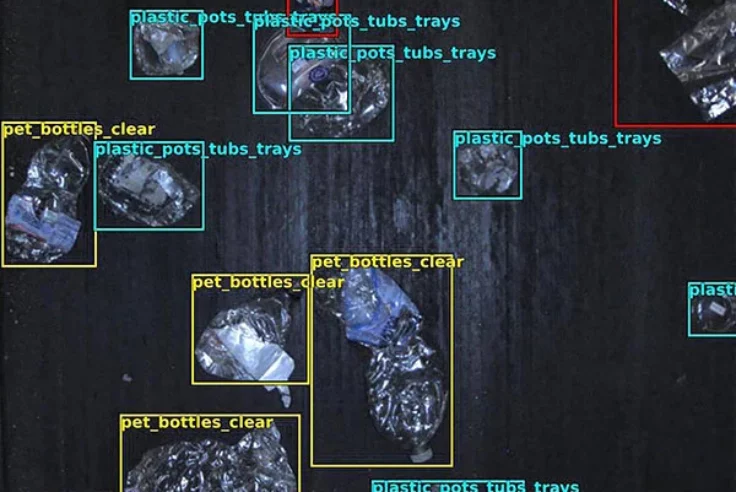

How AI Could Change the Way We Think About Recycling

Closed Loop Partners’ Center for the Circular Economy...

Reuse

Blog Post

Making Reuse an Everyday Reality: 3 Things We Must...

Reuse is now at a critical stage of development. A...

Molecular Recycling

Blog Post

What Is Chemical Recycling, Why Does It Have So Many...

Closed Loop Partners spent 18 months investigating...

Blog Post

The Most Sustainable Bag Is Likely the One You Already...

How often do you get to the checkout counter only to...