Molecular Recycling

What Is Chemical Recycling, Why Does It Have So Many Different Names, and Why Does It Matter?

August 15, 2023

Closed Loop Partners spent 18 months investigating the environmental impacts and financial viability of several types of molecular recycling technologies (sometimes also called advanced recycling or chemical recycling) to understand how and if these diverse technologies can fit into a circular future for plastics. Here’s what we found.

- Molecular recycling is a diverse sector that can be categorized into three distinct technology categories: purification, depolymerization and conversion.

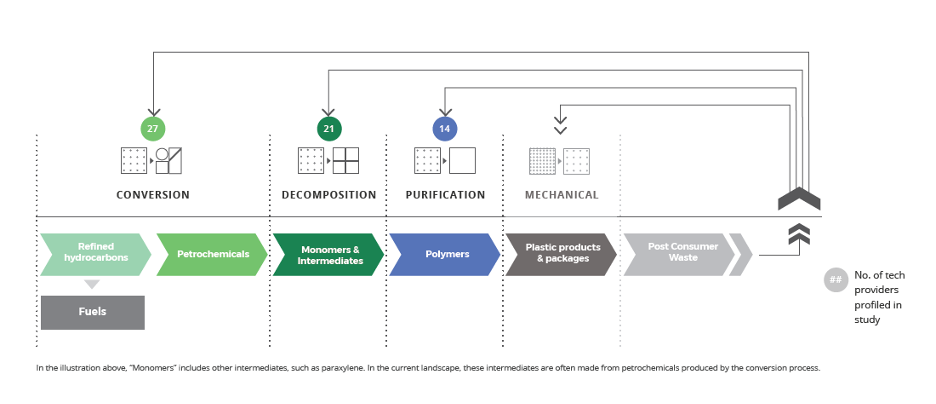

Figure 1: Molecular Recycling Technology Categories and Their Outputs

Molecular recycling is a broad umbrella term – also referred to as chemical recycling or advanced recycling – that encompasses dozens of technologies that use solvents, heat, enzymes, and even sound waves to purify or break down a wide range of plastic feedstocks to create polymers, monomers, oligomers or hydrocarbon products so that they can re-enter manufacturing supply chains, instead of going to landfill.

In other words, molecular recycling technologies can break down plastic waste into its constituent building blocks, which can then be used to create new plastic products. These technologies are only circular when their supply chains produce a final product. Converting plastics to fuel is not recycling or circular. Molecular recycling is a group of technologies that can complement mechanical recycling and help widen the aperture of plastic waste that we can recycle today.

- Molecular recycling is only one part of a suite of solutions to address plastic waste; both upstream and downstream solutions are needed, including design and reuse, as well as mechanical and molecular recycling, and policy.

Figure 2. The suite of solutions needed to reduce plastic waste

Molecular recycling is part of a suite of solutions needed for a circular plastics economy. It is not a silver bullet but plays an important role in creating a waste-free future for our hardest-to-recycle plastics which include the 41 million metric tons of textiles and approximately 2,000 wind turbine blades expected to go to landfill in the U.S. every year.

- Expanding the scope of plastics that we recycle is important given the diversity of plastics in our economy. We will not achieve a waste-free future unless we scale solutions that address all plastics.

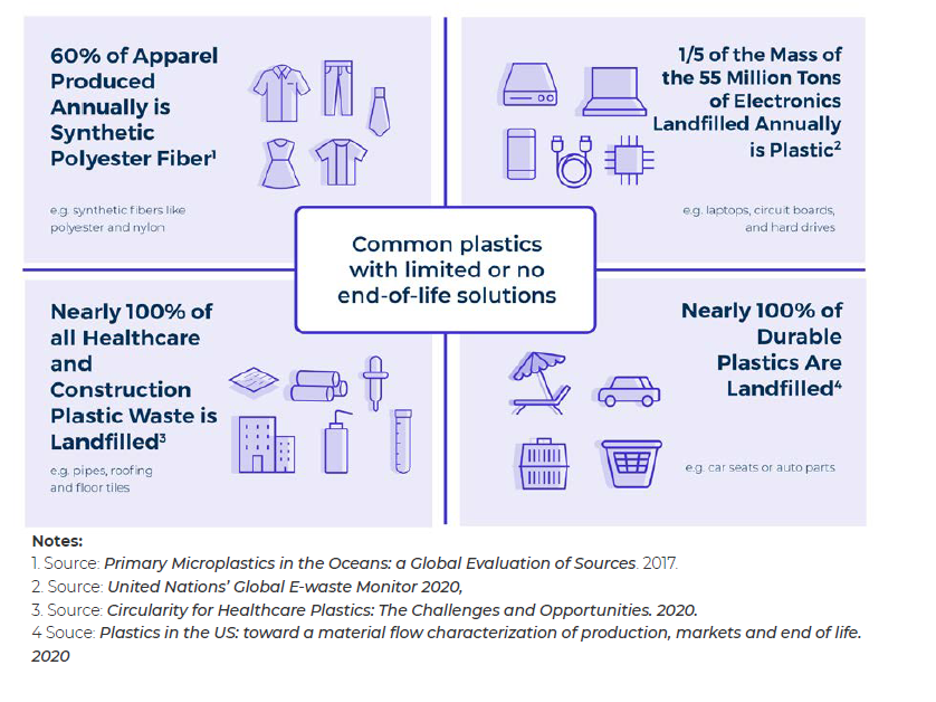

Figure 3. Common Plastics Without Commercial Recovery Solutions, Typically Sent to Landfill every year

The “plastics waste crisis” has been defined in the public and policy discourse as created by single-use plastics. Yet, two-thirds of plastics put into use in the U.S. today are used for purposes other than single-use packaging. These types of plastics are equally visible and challenging to recover and reuse.

- Molecular recycling can expand the scope of plastic waste we can recycle, helping to preserve the value of resources in our economy.

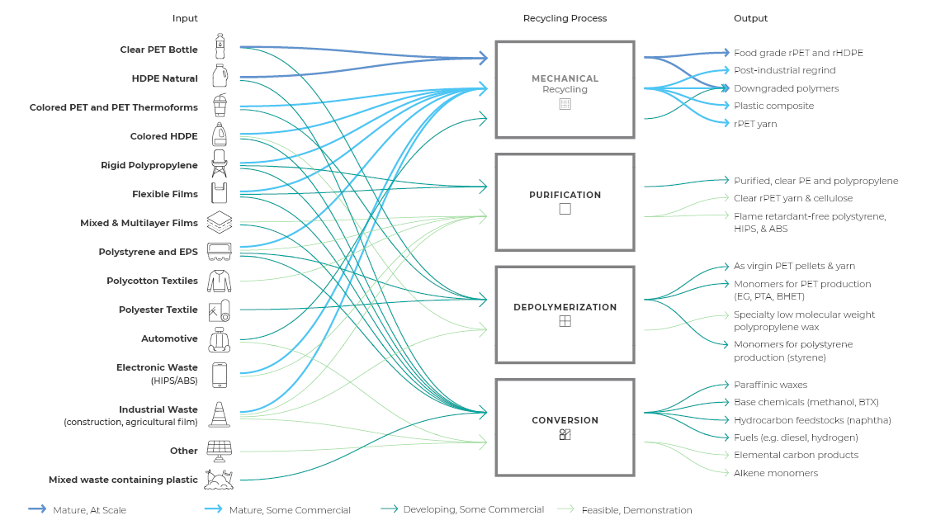

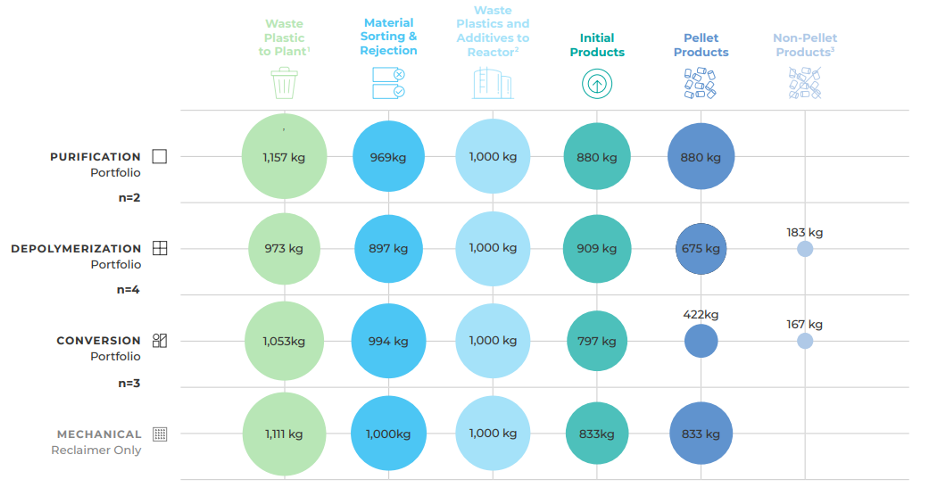

Figure 4: Inputs and outputs for mechanical, purification, depolymerization and conversion technologies from input to output.

Plastic is as ubiquitous as it is diverse. Our current mechanical recycling system is designed to address only a small fraction of plastics in the market – namely, plastic water bottles (PET), milk jugs (HDPE), and in some markets, yogurt cups (rigid polypropylene). Plastic packaging, like plastic film (LDPE) and clear boxy packaging that many salad mixes are sold in (PET thermoforms) are sometimes downcycled into plastic lumber. Textiles and durable plastics are recycled in lower quantities or not at all because there is less consistent demand for these recycled plastics. As a consequence, most plastic waste ends up in landfill.

Molecular recycling technologies can widen the aperture of plastic waste that we can recycle today beyond packaging. Purification technologies can process electronic waste and films. Depolymerization technologies, which largely focus on PET and polyesters, are a critical recycling solution for synthetic textiles including carpets and athletic clothing. Conversion technologies like gasification can even take mixed waste, breaking down feedstock to basic carbon and hydrogen atoms.

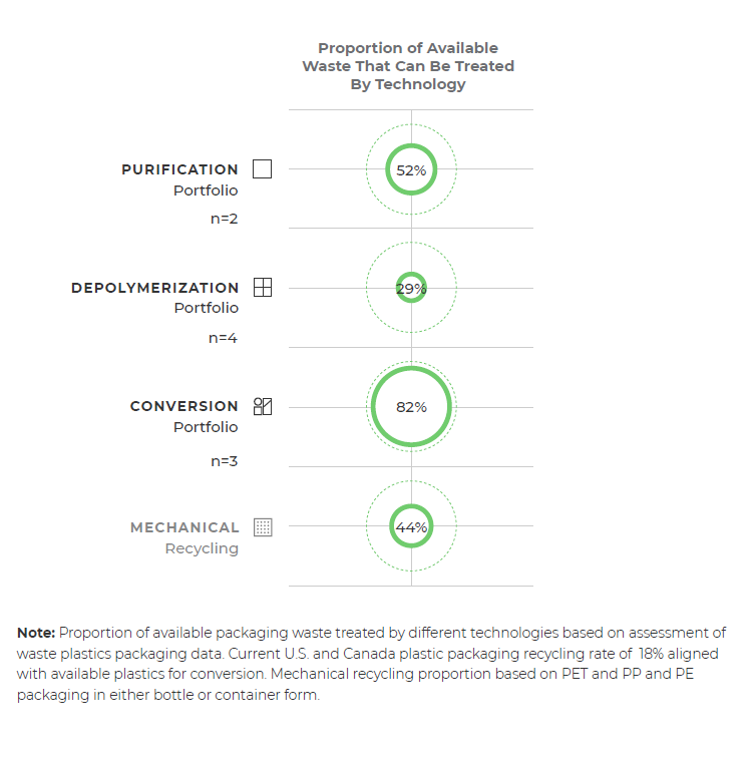

- Conversion technologies like pyrolysis and gasification can process the highest volume of plastic packaging and can accept mixed plastic packaging feedstock.

Closed Loop Partners evaluated nine different technology processes across the three technology categories. When evaluating the total packaging volumes across the United States and Canada, we found that the conversion technologies could accept 82% of all plastic packaging produced, which is more than mechanical, purification, or depolymerization technologies could address alone. These types of technologies also can process mixed plastic waste, while purification and depolymerization requires a sorted and single-resin feedstock. Because feedstock can be mixed, conversion technology companies are often paid to take feedstock rather than paying for feedstock.

Figure 5. Percent of US and Canadian Plastic Packaging that Closed Loop Partner’s Cohort of Molecular recycling Technologies could Address

- When considering downstream solutions, a critical metric of success is the amount of recycled plastic (PCR) that each technology solution can produce. The less a polymer is broken down through molecular recycling process, the more recycled plastic will be produced.

Each molecular recycling technology category has a distinct supply chain. For example, purification technologies produce finished recycled plastic. Depolymerization technologies produce monomers which would be sent downstream to be easily repolymerized back into plastic. Conversion technologies have the longest route back to becoming plastic. A pyrolysis technology company will produce pyrolysis oil which would be sent and processed by a steam cracker to produce monomers, which are then sent downstream to make plastic again.

Closed Loop Partners calculated how much plastic resin would be produced by each of the three main molecular recycling technologies discussed in this series (e.g., purification, depolymerization and conversion) if we were to put 1,000 kilograms of plastic feedstock into the technology reactor. Purification yielded the highest amount at 88% of material processing efficiency. Conversion technologies yielded the lowest amount of recycled plastic with a 42% processing efficiency. The capacity to move away from virgin plastics requires the recycling sector to be as efficient as possible.

Figure 6: Average mass yield when 1,000kg of plastic waste is put into each technology process

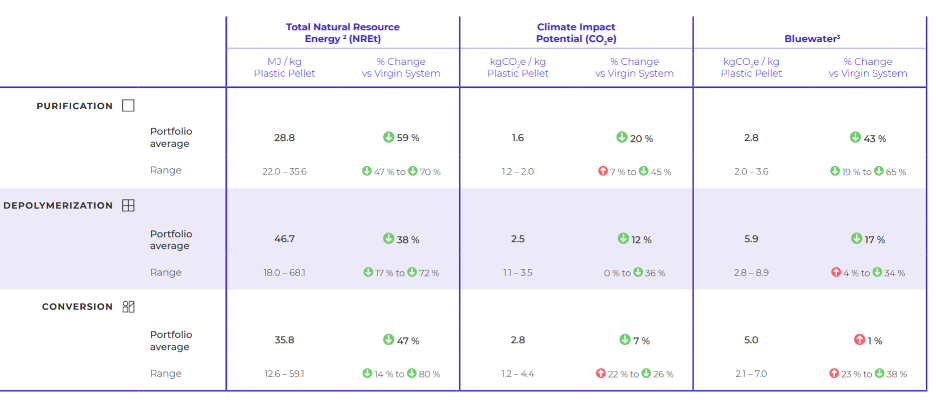

- From an environmental perspective, purification and depolymerization technologies have a smaller environmental footprint, on average, compared to conversion technologies.

Closed Loop Partners also analyzed the energy, greenhouse gases and water impacts of individual technology processes, and the systems-level impact of producing different polymers via purification, depolymerization and conversion technologies. On average, purification was the best performing category across all environmental measures, yielding 20% reduction in greenhouse gas emissions compared to the virgin plastics supply chain. Depolymerization had an average greenhouse gas reduction of 12%, while conversion technologies reduced carbon emissions by 7%, on average. Decarbonizing the plastics supply chain requires prioritizing the solutions that help to meaningfully improve the status quo.

Figure 7: Summary of environmental impacts to produce recycled plastic by technology category

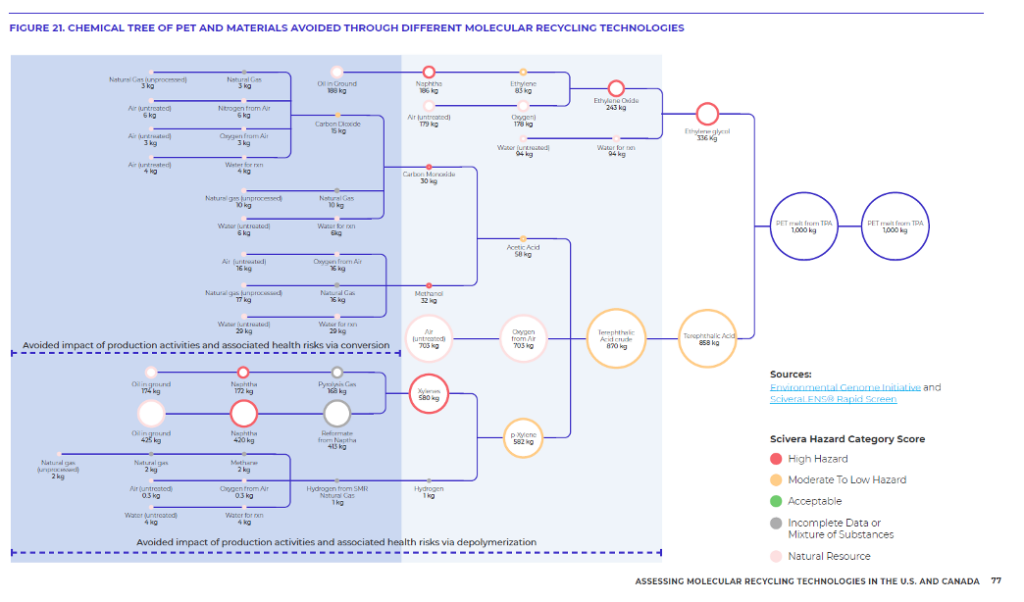

- The less a polymer is broken down through molecular recycling process, the fewer virgin petrochemical inputs are needed to make plastic again – which can reduce the human health impacts of plastic production compared to virgin plastic production.

Several chemical inputs are used to produce plastic. We’ve pictured the chemical tree to make PET which is the plastic used in water bottles. Because plastic can be recycled by many types of molecular recycle technologies, our team wanted to understand the potential human health impacts of different technologies. While qualitative in nature, our findings strongly suggest that the less a polymer is broken down through a molecular recycling process, the lower the human health risk because fewer chemicals and processing are

required to build back the polymer. In the illustration below, depolymerization technologies have an advantage over conversion technologies that can also process PET because depolymerization displaces more of the virgin supply chain to create an equivalent amount of plastic.

Figure 8: Summary of environmental impacts to produce recycled plastic by technology category

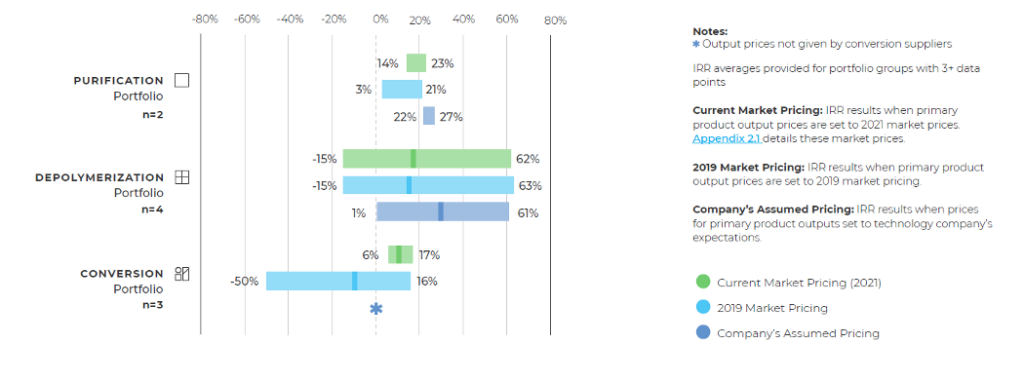

- The economic viability of molecular recycling technologies varies depending on several factors, such as the cost and accessibility of feedstocks and the market demand for the recycled products.

Analyses conducted by Closed Loop Partners over the course of 18 months across nine technology companies found that at least one technology company was financially viable in each category. Specifically, seven of the nine technology companies evaluated had a positive internal rate of return (IRR) ranging from 6% to 62% in the 2021 base case. It is also noteworthy that two-thirds of the technology companies in our study had positive IRRs, given that our base case assumes that these technologies are expected to sell their outputs at market commodity prices without a premium. Figure 5 above summarizes the expected rate of return across three scenarios: 2021 market pricing, 2019 market pricing, and the expected output pricing cited by the technology companies themselves.

Figure 5: Expected Internal Rate of Return (%) Ranges for Each of the Three Molecular Recycling Technologies

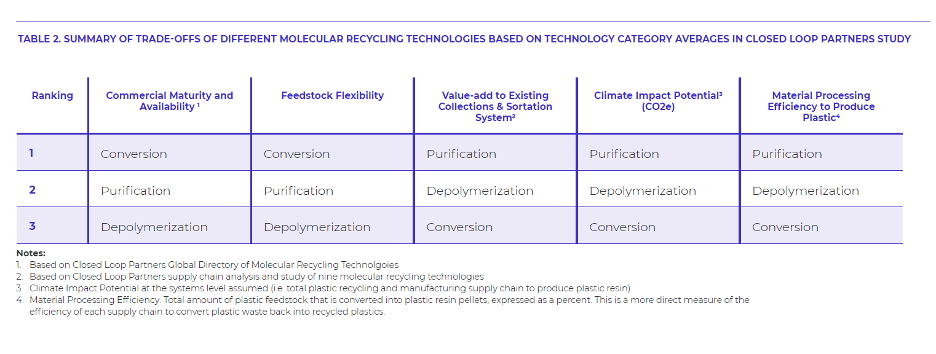

- There are tradeoffs to each molecular recycling technology category and type. The viability of one solution depends on those metrics that matter most to a brand, investor, or community.

The molecular recycling sector is incredibly nuanced and diverse. Not all technology groups are at the same level of development. Their tolerance for mixed plastics or other contamination varies company to company, just like their performance across environmental impact metrics like energy, water and greenhouse gas emissions. Due diligence prior to investing in strong performing technologies is critical. Closed Loop Partners has summarized the results when observing the category averages between purification, depolymerization, and conversion in the table below. This summary is based on our review of nine technology companies between 2020-2021 and should only serve as a point of data, not a definitive source on the state of the sector at large. The opportunity for consumer brands, policymakers, and investors is to collaborate to develop a vision of success for this sector.

To read our full report on molecular recycling technologies, including a list of more than 100 questions that investors and brands should ask when considering investing in this sector, visit Closed Loop Partner’s website.