The Hidden Value of Scrap Metal: Why Local Recovery Matters

May 28, 2025

For this edition of our Making Circularity Stick series, we explore the world of scrap metal processing with Emily Molstad, CEO of our portfolio company VALIS Insights.

Emily Molstad, CEO of our portfolio company, VALIS Insights, and Aly Bryan, Investor on the Closed Loop Ventures Group team at Closed Loop Partners, explore how the metals processing system in the U.S. is misaligned––with high value scrap going to low value applications far away from where it’s recovered. The discussion explores the core reasons for this misalignment, and how our portfolio company, VALIS, is supporting processors to make more money with local processing while keeping copper, nickel, aluminum and many other metals in domestic circulation.

There has never been a better time to strengthen metals circularity, and Closed Loop Ventures Group is energized to continue to support the VALIS team.

Aly: One of the things that’s always struck me about scrap processing in the U.S. is the amount of scrap that’s exported. After all, there are valuable materials in those exports! Copper, nickel, aluminum. Why is it that valuable scrap gets sent overseas today?

Emily: One of the biggest challenges in scrap metal is the fragmented nature of the secondary metals processing system––which produces alloys or remelts metal scrap to create new products. While there are several, multinational organizations operating in the space, huge volumes of scrap metal go through a localized system of processors within a region. This makes sense, since it wouldn’t be economical to lug every end-of-life car to a centralized processing facility. So instead, they’re processed at smaller facilities closer to consumers. However, those regional processors have long-standing customer relationships, which, historically, have been overseas, in areas where labor costs for manual sortation are low. This means that a lot of high value metals from local manufacturers are transported long distances and become commodities elsewhere, instead of being recaptured within the domestic market. This has remained the status quo for a long time, as scrap processors often prefer to sell how they’ve always sold, with hesitancy to take advantage of changing market conditions that allow them to operate more profitably while supporting national security of metals and minerals.

Aly: What do you mean by changing market conditions?

Emily: Let’s look at aluminum as an example. All the different types of aluminum, such as high-value wrought and lower-value cast alloys that are in our cars, home appliances and other products, are packaged into a recycled material specification known in the industry as “Twitch.” Historically all these mixed alloys were blended together and downcycled, or downgraded, into cast aluminum. This is because there was sufficient demand for cast aluminum. Wrought aluminum producers met their supply through other sources. Over time, the distribution of different types of aluminum alloys that are used in manufacturing has shifted. There’s now a considerable amount of high-value wrought aluminum that’s being lost when it’s downcycled, and wrought producers need more supply to meet growing demand, creating a market for sorting Twitch further into its cast and wrought fractions. This changing market condition was validated at the ReMA National Convention, with the association governance voting to approve a new industry specification called “Vesper,” which is defined as the wrought aluminum sorted from Twitch. There’s now language in place to support buyer and seller agreements, validating the growing demand for sorted products that drive the economics for investing in further processing of mixed scrap metal.

Aly: How does VALIS work with processors to improve their economics and sell inventory domestically?

Emily: At VALIS, we’re building integrated hardware and software solutions that help scrap processors improve the efficiency of their day-to-day operations. We provide them with tools to capture accurate, reliable data on their material quality so they can more effectively monitor their process and sell their products. All that quality data is tied into the digital twin we build of their entire processing line. By integrating with their equipment and capturing production information, we can give them full visibility into the performance of their operations, alert them to issues within their sorting process, and give them tools to predict production volumes based on historical performance. They can tie in pricing metrics to understand the economics of making changes to their operations or help them easily see how improving sortation would contribute to their profitability.

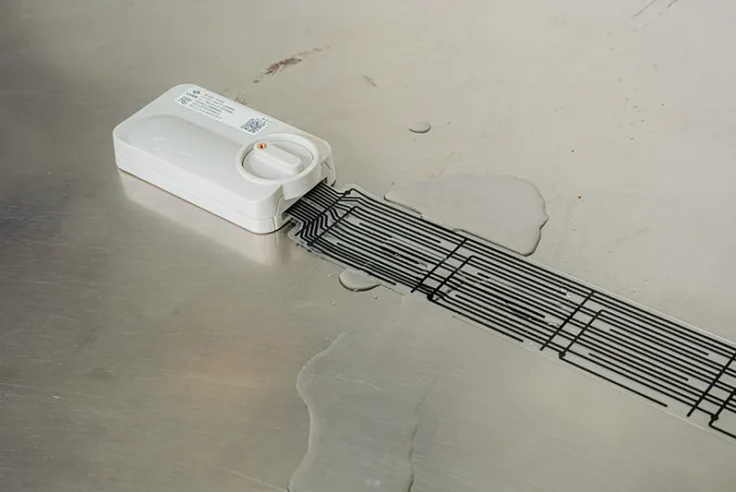

Aly: You’re in market today with VALI-Sample, your sampling product that provides a more efficient way to sample and track composition of drop-out and shredded products. Why have your partners chosen to roll out VALI-Sample across their plants?

Emily: It would be physically impossible to get a detailed analysis of all the metal running through a processing yard. Sampling helps gain visibility into material quality and value, and measure operational performance. Data generated during sampling then informs sales and processing decisions. But today, that data is captured on pen and paper, or analyzed in massive spreadsheets. That leads to human error and a lack of trust in the results. There’s also uncertainty around how well a sample represents reality. Without high quality, reliable data, decision makers are limited in the actions they can take to improve their business. VALI-Sample delivers the accurate data that processors need. It’s an easy-to-use hardware tool that delivers an improved work experience for sampling technicians. It is enabled by a powerful software platform that gives facility managers the ability to audit their sampling process, and sales managers the receipts on material quality they need to back up sales or defend against a claim.

Aly: Like many, I’ve spent more time talking and thinking about tariffs in the past four months than ever before. The metals industry was among the earliest hit––with tariffs on everything from aluminum to copper and steel. How are your customers able to be more agile and resilient to tariffs?

Emily: Tariffs can make it more expensive to import virgin metals for new manufacturing, incentivizing processors to find domestic solutions. Since so many of these metals are partially recovered domestically today, processors who are willing to go the extra mile and do the extra sortation step are going to be much better positioned to supply local smelters and ultimately local manufacturers of new products. By integrating our technology, we can help processors navigate these challenges and capitalize on the opportunities presented by the boom in domestic manufacturing.

Aly: As we close out our discussion, I’ll ask you the question I ask all our founders on “Making Circularity Stick”: What do we need to make circularity stick in the scrap metal industry?

Emily: In a phrase? Cross-value chain collaboration. Looking ahead, we believe that involving the entire ecosystem is key to making circularity the default way of doing things in metals. Automotive manufacturers need to be transparent on alloy specs and source recycled metals, metal producers need to increase recycled content in their systems, scrap processors need to improve the quality of their outputs to better match the requirements of mill processes, and so on. We need all of these actors to work together, challenging what’s possible, and continuously raising the bar on circularity in metals to get there. At VALIS Insights, we are proud to be at the forefront of making circularity stick in the metals recycling industry. By leveraging technology and data, we are partnering with our customers to transform the processing system and pave the way for a more sustainable future together.

“Making Circularity Stick” is a collection of interviews with founders across the Closed Loop Ventures Group portfolio sharing their experiences of making circularity stick across industries. If you’re interested in connecting with the founders sharing their stories, please reach out to Aly Bryan at [email protected].

Disclosure

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

Related posts

Press Release

Closed Loop Center for the Circular Economy Launches...

The Closed Loop Center responds to composters’ increasing...

Press Release

Closed Loop Partners Deploys Multi-Million-Dollar Loan...

The catalytic loan from the circular economy-focused...

Press Release

Closed Loop Partners Releases New Guidelines to Strengthen...

The new guide shares tactical best practices to help...

Press Release

Closed Loop Partners Deploys $10 Million Loan to TemperPack,...

This marks Closed Loop Catalytic Capital & Private...

Press Release

Closed Loop Partners’ Composting Consortium, With...

Eight municipal and composter-led projects received...

Blog Post

Materials Matter: Designing Reuse for the Real World

One of the most important design decisions for reuse...

Blog Post

How Smart, Scalable Sensors Are Reducing Waste in the...

Why We Invested in LAIIER, a Denver-based startup pioneering...

Press Release

Closed Loop Partners Advances Major Progress for the...

The circular economy-focused firm releases 2024 impact...

Press Release

Beyond the Bag Initiative Unites Major and Local Retailers...

Headlined by Target, CVS Health, Ralphs and Food 4...

Blog Post

Reuse Is Coming to U.S. Cities. Here’s How Businesses...

Reuse is growing across sectors — but it’s still...

Press Release

Beyond the Bag Initiative Releases Its Largest Study...

The Consortium to Reinvent the Retail Bag unveils insights...

Blog Post

For Reuse to Work, Language Matters

A quick guide to messaging for reuse programs and getting...