Climate

Why solving the climate crisis requires a transition to the circular economy

September 20, 2021

This article is part of Closed Loop Partners’ Climate Series, which explores the critical link between transitioning to a circular economy and addressing the climate crisis. By reworking the fundamental flow of materials in our economy, the circular economy offers an economically attractive, socially just and environmentally sustainable way to meet our global climate commitments.

- While the transition to renewable energy is critical to meeting our global climate targets, it will only address about half of our emissions.

- The remaining half are tied to the products and services we consume everyday.

- The circular economy provides the only economically attractive and environmentally sustainable way to transform our production and consumption systems in line with global climate commitments.

- There are already a number of successful circular economy business models that reduce extraction and landfilling costs and cut carbon emissions, paving a pathway forward.

Leaders from almost every nation on earth––197 countries––have signed the Paris Agreement to limit temperature rise to 2 degrees, with an agreement to aim for a 1.5 degree celsius limit. Nearly one-fifth of the world’s 2,000 largest public companies (representing $14 trillion in sales) have committed to net zero emissions.

So why are scientists, activists and leaders across sectors still worried about the climate crisis? Two important reasons come to mind:

- Our current policies push us close to 3 degrees rise in global temperature. Even our pledges only get us to 2.4 degrees.

- It’s not enough to transition to renewable energy. We also need to tackle carbon emissions in the stuff we create, buy, use and dispose of.

Our reliance on “dirty” and non-renewable energy is a significant contributor to our climate crisis, and a rapid and just transition to renewable sources of energy is critical to reducing global emissions. However, that’s only about half of the answer. Research from the Ellen MacArthur Foundation finds that our transition to renewable energy “can only address 55% of emissions. The remaining 45% comes from producing the cars, clothes, food, and other products we use every day.”

What does our linear economy have to do with the climate crisis?

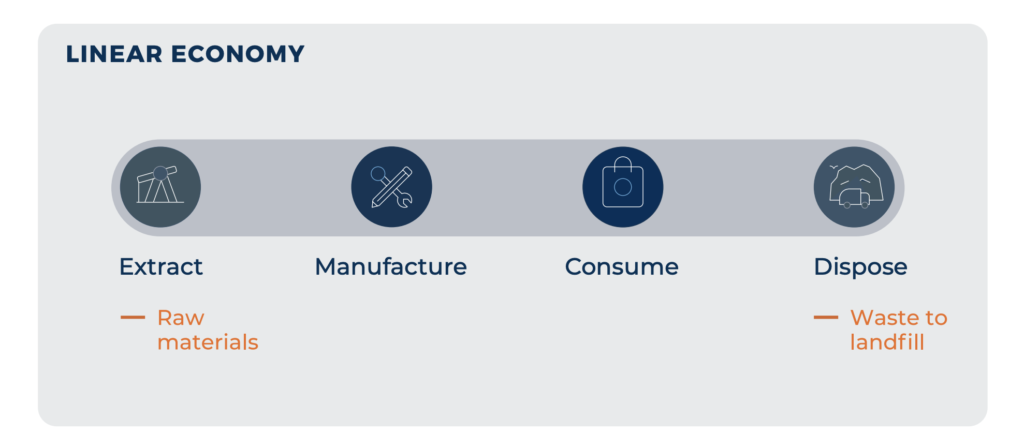

What’s wrong with our current methods of production and consumption? Today’s linear economy is based on a ‘take-make-waste’ model: we take natural resources (extraction) to make products (production/manufacturing) and when we’re done using them (consumption), we dispose of them (waste/landfilling).

LINEAR ECONOMY

At the take/extraction phase, this is an issue because we don’t have access to unlimited natural resources. Today, we are using about 1.6 earths; meaning we’re using about 50% more of the earth’s resources than it can regenerate every year. By 2050, with an increased global population and resulting rise in consumption, that “overshoot” could get to 3-4 earths, which is clearly unsustainable. From a climate crisis perspective, extraction––a key part of our linear economy––is responsible for “53% of the world’s carbon emissions” and “more than 80% of biodiversity loss,” according to a study done by UN Environment.

At the other end of the linear value chain, waste/landfilling is also directly contributing to greenhouse gas (GHG) emissions and our climate crisis. Why are landfills especially insidious? In addition to taking up otherwise productive land, this explanation from Waste Dive is especially helpful: “when trash is packed into a pile, the oxygen-free environment supports bacteria that thrive in those conditions. As the microbes degrade the waste, they release carbon dioxide and methane. The latter is…84 times more potent of a global warming agent than carbon dioxide in the first 20 years of its release.”

And while we know that methane released in landfills is particularly harmful to the environment, we are still learning about the extent of their impact. In the United States, a recent multi-year aerial study of “super-emitter landfills accounted for 43% of the measured emissions of the potent greenhouse gas methane––outpacing the fossil-fuel and agricultural sectors” while “the ten biggest methane-emitting landfills pumped out the gas at rates averaging 2.27 times the federal estimates.”

How does a circular economy help address the climate crisis?

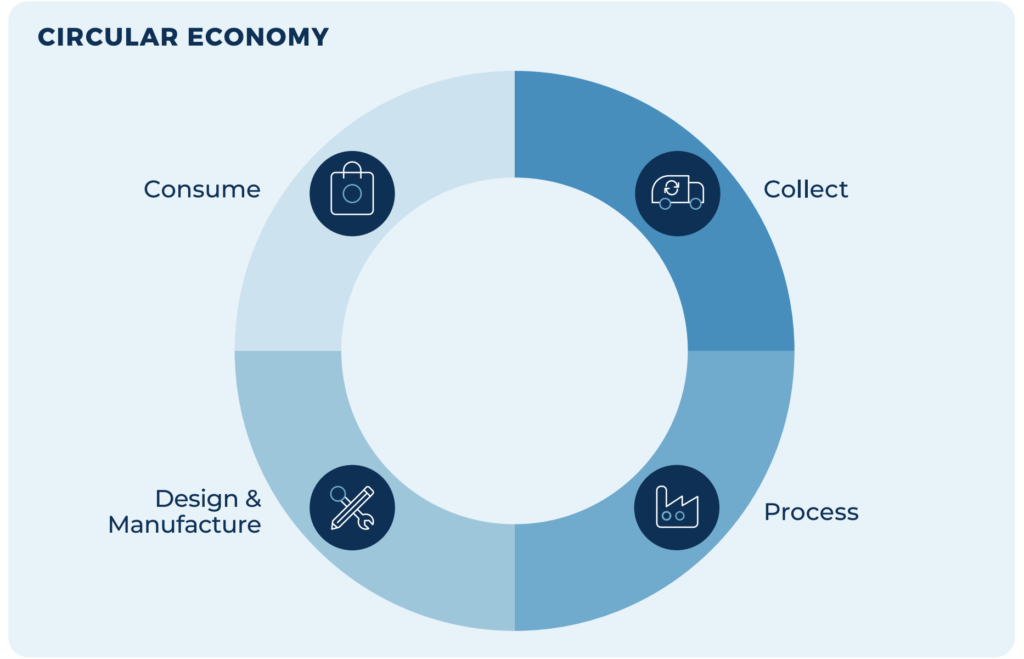

Transitioning from a linear to a circular economy is critical to addressing the 45% of emissions associated with our current models of production and consumption. Unlike the linear “take-make-waste” model described above, a circular economy eliminates the concept of waste altogether, moving us into a more closed loop system where materials and products are kept in use as long as possible. In doing so, the circular economy tackles some of our greatest social and environmental challenges while unlocking $4.5 trillion in economic value by 2030.

CIRCULAR ECONOMY

As you’ll notice in the diagram above, the two emissions-heavy ends of the linear value chain––extraction and landfilling––are eliminated, as they are not valuable in a circular economy. How do you eliminate such prevalent parts of today’s value chain?

Let’s start with extraction of natural resources. Since the beginning of the first industrial revolution, we’ve had a nearly 1:1 relationship between economic growth and the use of natural resources. According to UNEP, global extraction of natural resources has more than tripled since the 1970’s and by 2060, “global material use could double to 190 billion tonnes (from 92 billion), while [GHG] emissions could increase by 43%.” While improving resource efficiency is helpful, our current and projected extraction rates (and associated GHG emissions) are largely influenced by increased consumption and our reliance on single-use products and packaging made from finite natural resources, like fossil fuels.

In a circular economy, the use of toxic, single-use or non-renewable inputs are reduced, and ideally eliminated. Circular design and sourcing instead favor inputs that do not rely on extraction of natural resources, valuing materials that are renewable, regenerative, reusable and recyclable.

But we can’t just focus on better and more sustainable inputs to our products. Valuable materials, including those that are naturally sustainable like food, can still end up as “waste” in the environment and in landfills, resulting in carbon dioxide and methane emissions. Today, the world produces over 2 billion tons of solid waste, and that’s expected to grow to 3.4 billion tons by 2050. By volume, global waste includes 44% food and organics, 17% paper and 12% plastic––all materials that could be valuable in a circular economy.

By keeping products and materials in play as long as possible––by extending the life of products and reprocessing materials at end of use––the circular economy eliminates the need for both extraction of natural resources and landfilling or incineration of goods. Circular systems prioritize local, “short” material loops in which communities benefit from valuable materials re-entering local manufacturing supply chains, creating new jobs, spurring innovative end markets and fostering a healthier environment. By advancing local solutions, the circular economy provides more communities with the tools needed for resilience against a globally changing climate, and, of course, reduces or eliminates the significant GHG emissions and economic costs associated with the linear economy.

How can we accelerate our climate commitments through the circular economy?

Investments, innovations and regulations that encourage a circular economy see materials as valuable commodities rather than products of a single-use, extractive-intensive and wasteful society. Let’s explore a few examples across the linear to circular value chain.

Keeping materials in play. Over 500 companies have signed the Global Commitment for a New Plastics Economy, including the world’s largest consumer goods companies. At the same time, less than 9% of plastics are recycled globally. Investments in the collection, sortation and reprocessing of materials – including plastics, glass, paper, aluminum, etc. – are critical to keeping materials in play and reducing what is sent to landfills. For example, Eureka Recycling, a locally operated nonprofit Material Recovery Facility (MRF) in Minneapolis, was able to increase its recovery of recyclables by 13% by upgrading equipment to improve sortation capacity. This resulted in 1 million pounds more of PET plastic recovered annually, which is the same as almost 20 million plastic water bottles. If lined up, this would be enough water bottles to connect New York to San Francisco. By keeping these valuable commodities out of landfills, we reduce the need for extraction to produce virgin plastics.

Some materials can be more difficult to recycle or reprocess at the end of use. Cotton, a highly resource-intensive crop, is an example of a popular material that is not often reprocessed or recycled, especially post-consumer use. Circular startup Evrnu has developed a novel technology to transform challenging textiles like 100% post-consumer cotton into new, like-virgin materials. Similar to the example above, this kind of solution eliminates the need, costs and emissions impact of extraction (production of virgin cotton) and landfilling (used cotton to waste).

Finally, some materials like organics––food scraps, yard and agricultural waste, human waste, etc.––are not a great candidate for reuse or reprocessing. In a circular economy, we can turn organics into valuable sources of energy and fertilizer. Israel-based HomeBiogas uses anaerobic digestion to convert organic materials into fuel for cooking or hot water. In addition to reducing the costs and emissions associated with sending food waste to landfills, this circular solution creates valuable products that reduce the need for extraction (e.g. cooking fuel) and improves soil health (e.g. natural fertilizer).

Switching to more sustainable materials. Rather than focusing on the end-of-life of products and keeping materials in play via models like recycling, some circular solutions are focused on alternative materials that are less extractive and more sustainable from the outset, while still maintaining the same performance as traditional materials. Algaeing, for example, is using biodegradable and energy-efficient algae as an alternative material for fashion and textiles. In addition to reducing the use of water and eliminating the need for toxic chemicals and pesticides commonly used in textiles, their algae alternative reduces the costs and emissions associated with both extraction/production and landfilling of materials like cotton and polyester.

Reducing the need for materials. Half of all packaging is designed to be used only once––also known as “single-use packaging”––and then thrown away. Most often, that packaging is not the primary source of value of a product, as we’re usually buying what’s inside. Think of a bottle of shampoo or detergent – a big part of the item cost is for the packaging, which doesn’t really offer value to the consumer. Started in Chile to address economic and environmental issues associated with the packaging of household staples like cleaning supplies, Algramo’s smart vending machines dispense products “by the gram” (hence the name!) into reusable containers. This reduces both the environmental impact and cost associated with single-use packaging, and provides a much more convenient way for people to buy common goods.

Extending the life of our stuff. Outside of single-use packaging, more and more “durable” items are prematurely thrown away, despite having multiple uses or “lives” left in them. This is exacerbated by the rise in on-demand purchasing via eCommerce and “fast consumption” lifestyles. Several startups are looking to reverse this trend, by finding both economic and environmental value in circular business models that extend product use to multiple consumers. For Days, for example, has developed a circular business model for typically fast fashion items like t-shirts and sweatshirts. They incentivize customers to return clothing at end of use through discount pricing and reverse logistics, keeping apparel out of landfills.

We can even extend the life of organic products like food. As mentioned above, food waste is a significant part of landfills and a dangerous contributor to both methane production and food insecurity. Start-up Mori has developed a tasteless and sustainable coating, inspired by the Mori silkworm, to extend the life of perishables like fruit, vegetables and seafood. In addition to reducing the amount of food waste that ends up in landfills (contributing to climate change via methane emissions), Mori’s solution also reduces the need for food packaging, further reducing emissions and costs associated with the extraction and landfilling of single-use packaging.

So, what’s next?

Circular economy business models offer a clear pathway toward achieving our collective climate goals, tackling the greenhouse gas emissions tied to the extraction, processing, manufacturing, and landfilling of goods. Already, there is a burgeoning ecosystem of innovators that are breaking away from the take-make-waste linear business model in favor of a circular economy, in doing so benefitting people, the planet, and business.

Next in Closed Loop Partners’ climate series, we’re going to explore how we can enact change more quickly to accelerate the transition to circularity. What are the levers we need to collectively pull? Who are the key stakeholders involved? What are we asking of governments and corporations?