How Businesses Can Spark a Cultural Shift Towards Reduction and Reuse in Foodservice Packaging

June 25, 2024

9% of Americans report bringing their own refillable cup when purchasing their coffee on the go. What needs to be true for that number to increase?

The Center for the Circular Economy at Closed Loop Partners shares insights on how businesses can align with customers in reducing cup waste, drawing on lessons learned from 90 Bring-Your-Own-Cup (BYOC) initiatives in cafés and restaurants across the U.S.

Read more to learn about our insights.

The Opportunity of Catalytic Capital

May 14, 2024

Closed Loop Partners is proud to celebrate 10 years of building the circular economy. This blog is part of a series of insights to mark this milestone, highlighting key advancements over the last decade––and the continued work needed over the next decades to accelerate the transition to the circular economy.

For 10 years, our thesis at Closed Loop Partners has remained consistent. The linear economy of materials management––characterized by extraction, single use and disposal––is inefficient. A more effective system exists: a circular economy, whereby people and businesses are custodians of materials over perpetual life cycles. The circular economy creates new value––a fundamental shift in the way society has managed resources over the last 75 years. But to sustain itself well into the future, circularity must be more profitable than the linear system.

Closed Loop Partners saw the economic, environmental and social opportunity in circularity. It was one of the first investment firms to bring together incumbent and emerging players to collectively accelerate this transition. As the firm enters its tenth year, cross-industry stakeholder participation continues to prove its effectiveness in advancing systemic change. Today, markets are experiencing the momentum driving the acceptance and understanding of circularity. Tailwinds including technological innovation, consumer sentiment, regulatory incentives, net-zero commitments and the need for supply chain resiliency propel the current transition. As the circular economy disrupts the status quo, it also presents investment opportunities, inviting collaboration across unexpected corporate, financial, government and community stakeholders.

The opportunity of the circular economy goes far beyond recycling. It represents full systems change, revamping each point in the supply chain: product design, logistics technology, collection capacity reprocessing and remanufacturing. Industries from consumer package goods (CPG) to food & agriculture, retail, technology, energy and the built environment stand to benefit from more efficient management of materials such as plastics & packaging, organics, textiles and critical minerals. To advance systems change across the product life cycle of different materials, different forms of financing are needed.

Today, Closed Loop Partners manages three primary investment strategies: early-stage venture capital, buyout private equity and private credit and catalytic capital. But 10 years ago, our work started with catalytic capital, to amplify the opportunity of circularity and to crowd traditional investment into the capital gap for the transition. 10 years later, it continues to be a critical piece of the puzzle.

Alongside traditional equity and debt solutions, catalytic capital––defined as flexible financing that prioritizes specific outcomes over prevailing market returns––can send a market signal to direct capital flows. This accelerates the uptake and scale of private businesses, municipal projects and infrastructure that are key contributors to durable, circular operations. For a decade, our catalytic investments, provided by Closed Loop Partners’s Infrastructure Group, have been connecting profit incentives with urgent environmental and social impact outcomes. Backed by global retailers, consumer package goods, technology and material science corporations and foundations such as Walmart, Unilever, Starbucks, PepsiCo, P&G, Microsoft, Keurig Dr Pepper, Kenvue (formerly Johnson & Johnson Consumer Health), Danone, Colgate-Palmolive, The Coca-Cola Company, BlueTriton, Amazon and 3M, these private credit and hybrid investments support innovations, private businesses, municipal projects, equipment upgrades and facility development.

By deploying below-market rate and more flexible financing than would otherwise be available, the Closed Loop Infrastructure Group aims to:

- attract follow-on capital from traditional capital markets

- increase the quality and quantity of recycled material kept in the system

- mitigate greenhouse gas emissions

- create more jobs across communities

- advance corporate strategic goals of integrating circularity into their operations.

As early champions of catalytic capital, Closed Loop Partners has worked with an array of municipalities and private companies to accelerate the transition to a profitable and more sustainable system. 10 years in, we have seen the ability of this financing to catalyze the market, in more ways than one.

- Catalyzing More Capital: rPlanet Earth was founded to provide high-quality recycled PET (rPET) packaging and containers to food, beverage and other CPG companies. Operating under a single roof, it is the world’s first completely vertically integrated manufacturer of multiple high rPET content products (up to 100% rPET), creating a much-needed market for the PET packaging collected from curbside recycling programs across California. rPlanet Earth is committed to providing the lowest carbon footprint packaging and products in the marketplace. In 2018, Closed Loop Partners identified the opportunity to bridge a near term capital gap and send a market signal. Our catalytic group provided a $1.5 million loan. Grants and loans from California’s Department of Resources Recycling and Recovery (CalRecycle), CAEATFA and private debt financing sources also provided alternative financing solutions. Also, one of the four largest banks in the U.S. provided a multi-million-dollar loan to finance the construction of their first facility. Together, this capital, along with substantial equity investments from two prominent funds financed rPlanet Earth’s first plant in Vernon, CA.

- Catalyzing Growth: By 2019, Phoenix, Arizona had risen to the fifth largest metropolis in the United States, resulting in a higher volume of recyclable materials. With a $3 million investment from the Closed Loop Infrastructure Group, the City of Phoenix upgraded its North Gateway materials recovery facility (MRF) to enable greater diversion of plastics from landfill and to improve the quality of baled paper produced. The upgrade also helped to increase the overall tonnage of residential recycled materials processed and recovered by the City’s MRF by over 25% within the two years after investment. The city has established a strong reputation for its commitment to the circular economy and its zero waste plan.

- Catalyzing Scale: In 2022, the Closed Loop Infrastructure Group invested in Greyparrot, a leading AI waste analytics platform for the circular economy. Their AI Waste Recognition System is deployed on moving conveyor belts in sorting facilities globally, with the mission of using AI to significantly improve recycling efficiency and increase resource recovery. Supported by funding, Greyparrot has grown to now identify over 25 billion waste objects each year, with 100+ of its Greyparrot Analyzer Units spread across more than 17 countries, and is working with three of the top eight global waste management companies.

Our future requires an increase in material circularity and urgent climate action. Our work at Closed Loop Partners advances efficient materials management and optimized supply chains in a more profitable, more resilient circular system. There is significant opportunity to transition the over $100 trillion global economy from the incumbent linear economic system characterized by wasted resources and profit leakage, to a more efficient circular economy. The Circularity Gap Report estimates that as of 2023, just 7% of the global economy was circular. There is over 90% of the economy yet to transition across materials including paper, metal, plastic, organics, water, critical minerals and carbon itself, and across industries from CPG to fashion, from technology to transportation, energy to real estate.

The transition to circularity presents trillions of dollars of opportunity. Catalytic capital can spark capital flows and accelerate scale, making the innovations, businesses, municipal projects and infrastructure that are critical to a profitable circular system move faster than they otherwise would. For potential collaborators––corporate, foundation, municipal finance or other institutional capital––that would like to learn more, please get in touch with our team. Join us in accelerating the transition to a market-driven circular economy and, in doing so, build a climate-positive future.

—

*This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Partners or any company in which Closed Loop Partners or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Information provided reflects Closed Loop Partners’ views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision.

Why We Invested in Capra Biosciences: How Microbes Are Changing Manufacturing

April 29, 2024

Today, we are witness to a rapidly changing manufacturing landscape, driven by demand for low cost, resilient (localized and more distributed) manufacturing and processing, with less reliance on feedstocks from complex global supply chains. In addition to AI, robotics and other advances in manufacturing, we see immense opportunity in the efficiency of the smallest of organisms: the microbe.

Microbes are behind well-known industrial processes: from yeast for leavening bread or producing ethanol to acetic acid bacteria for vinegar production. These processes typically start with some sort of carbohydrate or sugar-rich feedstock, in which the living organisms are added and allowed to eat their way through the feedstock in a process known as fermentation. Closed Loop Partners has long been exploring the prospect of using microbes to advance circularity, such as creating energy from food waste––as seen through the work of one of our earliest portfolio companies, HomeBiogas. Today, we are seeing even more opportunities for microbes to change the way we produce, and this drove our investment in Capra Biosciences.

Capra sits at the confluence of synthetic biology, resilient supply chains for national defensive strategies, and sustainable consumption. Capra leverages a unique microbe to consume organic feedstocks (like food waste) and convert those materials into high value molecules that are direct replacements for petrochemical-derived products. This can range from molecules used in cosmetics to high value lubricants.

In taking these waste feedstocks and upcycling them into some of the highest value end products, Capra demonstrates how synthetic biology sits at the heart of the circular economy:

- Reducing reliance on extractive industries: Capra is displacing petroleum-based feedstocks for hydrophobic chemicals. This eliminates the need for extractive mining processes and instead leverages waste feedstock to produce high value commodity products at a price point that is competitive with market incumbents.

- Leveraging waste feedstock: Synthetic biology is often reliant on sugars as feedstock for the microbes, which come from net new agricultural production. Capra is starting with food-waste derivatives that are widely available. By giving these materials another life, Capra diverts food waste from landfill and offers a more sustainable product.

- Process-flow material recovery: An ideal system is one in which the microbes and solvents can be recovered after one pass through the system, leaving a close to zero waste process and positively impacting unit economics.

- Distributed, on-site generation: Capra’s technology design allows for continuous flow and modularity, meaning they can convert waste carbon sources such as food waste into high value chemistries onsite. By keeping production and distribution local and integrated, their process helps reduce emissions associated with transportation.

Given the promise of synthetic biology, we are proud to be backing the expert team of Liz Onderko, PhD and Andrew Magyar, PhD, co-founders of Capra Biosciences. We have compiled a diverse syndicate of support, including SOSV, GS Futures, First Bight, E14 and others to support Capra in their work to make high performance and affordable renewable chemicals for the circular economy. Learn more about Capra Biosciences here or reach out to [email protected].

About Capra

Capra Biosciences is venture-backed startup company focused on sustainable production of petrochemical replacements from waste carbon using their proprietary bioreactor platform. Capra Biosciences is located in Sterling, VA. To learn more about the company, visit www.CapraBiosciences.com

About the Closed Loop Ventures Group at Closed Loop Partners

Closed Loop Partners is at the forefront of building the circular economy. The company is comprised of three key business segments: its investment arm, Closed Loop Capital Management; its innovation center, the Center for the Circular Economy; and its operating group, Circular Services. Closed Loop Capital Management manages venture capital, buyout private equity and catalytic private credit investment strategies. The firm’s venture capital group, the Closed Loop Ventures Group, has been investing early-stage capital into companies developing breakthrough solutions for the circular economy since 2016. The Closed Loop Ventures Group’s portfolio includes companies developing leading innovations in material science, robotics, agritech, sustainable consumer products and advanced technologies that further the circular economy. Closed Loop Partners is based in New York City and is a registered B Corp. Closedlooppartners.com.

—

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Partners or any company in which Closed Loop Partners or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Information provided reflects Closed Loop Partners’ views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision.

10 Years of Building the Circular Economy

April 11, 2024

Closed Loop Partners is proud to celebrate 10 years of building the circular economy. This is part of a series of insights to mark this milestone, highlighting key advancements over the last decade––and the continued work needed over the next decades to accelerate the transition to the circular economy.

In January 2014, Doug McMillon, the CEO of Walmart, invited the CEOs and leadership of Unilever, P&G, PepsiCo, The Coca-Cola Company, Kenvue (formerly Johnson & Johnson Consumer Health) and Keurig Dr Pepper to join him on stage at the annual meeting of Walmart’s suppliers. It was a groundbreaking moment. Some of the world’s largest corporations announced that they had joined together as the founding investors in the Closed Loop Fund, the inaugural fund of Closed Loop Partners, and one of the first investment funds focused on financing the development of the circular economy.

It was a monumental first step toward changing the trajectory of how we use our planet’s resources––away from a ‘take-make-waste’ economy and toward a waste-free world designed around resource efficiency, driving economic growth. This is the beginning of our story at Closed Loop Partners.

Several key factors led to that moment on stage. My journey before Closed Loop Partners had given me a clear view into the economic opportunity of rebuilding antiquated and inefficient supply chains into efficient and circular supply chains that continually reused materials in local markets. An urgent waste crisis, an increase in environmental regulation and growth in consumer demand for environmental responsibility, coupled with the emergence of circular innovations, made developing the circular economy so important to the future of business that it brought competitors together to form the Closed Loop Fund. This collaboration by industry leaders helped lay the foundational infrastructure for the circular economy in the U.S.

A few years later, as the circular economy gained momentum, our original Closed Loop Fund attracted additional corporate investors, including 3M, Amazon, BlueTriton, Colgate-Palmolive, Danone and Starbucks, catalyzing more capital into circular economy infrastructure. As our ecosystem grew, adding more strategies and asset classes, it attracted capital from financial institutions, including funds and accounts managed by BlackRock, leading family offices and foundation endowments. To meet the growing interest in the circular economy, the vision of Closed Loop Fund was expanded into other strategies, now comprising Closed Loop Partners.

What started with one fund a decade ago has grown into three businesses that form the Closed Loop Partners ecosystem, focused on three key development areas of the circular economy: our investment arm, Closed Loop Capital Management, invests in circular solutions across venture capital, catalytic private debt and buyout private equity strategies; our innovation and advisory group, the Center for the Circular Economy, advances critical research and manages unprecedented pre-competitive industry collaborations; and our operating group, Closed Loop Builders, houses our first operating company, Circular Services, the largest privately held recycling company in the U.S.

As I look back, some of Closed Loop Partners’ earliest catalytic investments demonstrate our founding vision and the foundation of the circular economy:

- A decade ago, as changes in global policy highlighted the need for local circular economy infrastructure in the U.S., investments in recycling capacity expansion became critical. Eureka Recycling, a recycling company servicing Minneapolis and St. Paul, Minnesota, was a first mover in elevating U.S. recycling, leveraging their operational experience and engaging with policymakers, industry leaders and community advocates to influence systems change. Financing from Closed Loop Partners over the past 10 years supported a three-fold increase in Eureka’s polypropylene plastic recovery. Since then, they continue to be a leader in setting the standard for best-in-class recycling operations and infrastructure.

- As the circular economy grew in the U.S., upgrades to municipal recycling systems were needed to keep pace with a growing volume of recovered materials. When aging recycling equipment needed replacing, the Waste Commission of Scott County pursued the change from dual- to single-stream recycling to improve material collection. Closed Loop Partners’ first loan nearly 10 years ago enabled the purchase of larger carts for curbside recycling and a redesigned single-stream MRF. The success of our first municipal loan catalyzed follow-on loans in 2018 and 2022, now enabling the county to serve 185,000+ households and process over 40,000 tons of paper, metal, glass and plastic per year.

- The onset of corporate waste reduction goals also meant a rise in demand for alternative packaging. TemperPack was one of our first investments to advance new sustainable materials. TemperPack developed the first high performance, curbside recyclable thermal packaging for shipments of perishable goods such as food and pharmaceuticals. Today, they continue to be a leader in packaging innovation, with a range of solutions that protect products, strengthen brands, and keep waste out of supply chains.

- Innovative circular solutions include new technologies that can work alongside material reduction, reuse and mechanical recycling to recover hard-to-recycle materials. One of our first investments was in PureCycle Technologies––its patented recycling process, developed by P&G and licensed to PureCycle Technologies, separates color, odor and any other contaminants from plastic waste feedstock to transform it into virgin-like resin. PureCycle closes the loop on the reuse of recycled plastics while making recycled plastics more accessible to companies looking to use a sustainable, recycled resin.*

Since these catalytic investments were first made, the market has matured and Closed Loop Partners’ work has expanded to include venture capital and buyout private equity, as well as innovation advancement, infrastructure development and circular materials management. These early investments were a market signal, and our work today is a foundation upon which we will invest in and build the circular economy over the coming decades––as profitability attracts more investment and as supportive policy accelerates tailwinds for incumbent supply chains to transition to circularity.

Closed Loop Partners now supports over 1,000 jobs across its ecosystem, all dedicated to advancing the circular economy. We are proud to work with leading organizations, cutting-edge innovators and over 50 of the world’s largest corporations committed to reducing waste across multiple areas––including plastics & packaging, organics, textiles and electronics. Closed Loop Capital Management manages over $500 million and has invested in over 80 companies, municipalities and organizations accelerating circular solutions. Together, our investments have kept 6 million tons of material in circulation and avoided 17.5 million tonnes of greenhouse gas emissions to date. The Center for the Circular Economy has led groundbreaking industry-leading pre-competitive collaborations that are focused on solving some of the most complex supply chain and manufacturing challenges, including reduction, reuse and recovery solutions for foodservice packaging and retail bags. And most recently, with over $700m in commitments from Brookfield, Microsoft, Nestlé, PepsiCo, SK Group, Starbucks and Unilever, we launched Circular Services, which is now the largest privately held recycling company in the U.S. It operates 20 recycling facilities and serves some of the largest municipal contracts in the nation including New York City, Palm Beach County, Austin, San Antonio and Phoenix.

Closed Loop Partners has evolved as the circular economy has advanced. Today, the circular economy is recognized as a core solution to climate change mitigation as we all as a template for more efficient business operations. As more stakeholders recognize the financial and environmental opportunity of the circular economy, billions of dollars are beginning to move toward circular systems. More industry leaders are collaborating around shared waste reduction goals, leaders of countries are working together on a global plastics treaty, U.S. states are proposing and passing bipartisan Extended Producer Responsibility (EPR) legislation to fund recycling programs, and C-suites of Fortune 100 companies are pushing to achieve ambitious publicly stated circular economy and climate goals.

Transforming entire supply chains across multiple industries is the work of generations, but the world is changing faster today than it was 10 years ago. As Closed Loop Partners enters a new decade of action and impact, we see a future ripe with opportunity. We are now at a pivotal point, and the next decade will be critical to delivering outcomes and building transparent, circular systems. There is much more work to be done in the next phase of this systemic shift, but together with strategic partners, and across our platform, we are focused on expanding our impact and rebuilding industries to follow nature’s lead––grounded in resource regeneration and positioned for a resilient future.

As we celebrate this milestone in 2024, we will be sharing key insights on our impact over the last 10 years, and what is to come in the next decades of building the circular economy.

We invite you to join us in the transition to the circular economy.

—

*In October 2020, PureCycle Technologies fully paid off its loan from Closed Loop Partners, thus exiting the Closed Loop Infrastructure portfolio as a borrower. The Closed Loop Partners team, however, continues to engage with the PureCycle Technologies team as they continue growing their operations.

*This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Partners or any company in which Closed Loop Partners or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Information provided reflects Closed Loop Partners’ views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision.

Why We Invested in VALIS Insights: Bringing Circularity to the Metals Processing Industry

March 18, 2024

This blog is part of our “Why We Invested” series, which offers a deep dive into our most recent investments and the growing circularity trends in the space.

The way scrap metal is processed today is a mystery to most outside the industry. When a car or an appliance reaches the end of its useful life, most of us often rely on a junk removal service––or hope that the retailer selling the new equipment will take the old one with them on the way out. What happens after that?

Emily Molstad, Caleb Ralphs and their team at VALIS Insights have spent the past five years getting to know these markets in minute detail. Imagine spending days and nights captivated by how metals are processed in the U.S. after they’re done being used. Imagine coming face-to-face with the information asymmetries in the system that result in mixed metals being shipped overseas instead of recovered for local use. Imagine having hundreds of conversations with processors, metals refiners and customers of virgin and recycled metals to better understand why the system is built the way it is and where there are opportunities to improve it. That’s what this team has done so comprehensively over the past few years, driving toward the creation of their AI-powered software that is closing the loop on a circular economy for metal fabrication.

Today, used metals are still dramatically under-recovered in the U.S. Recycling rates for many non-ferrous and ferrous metals lag below 60%, despite the high resale value of these materials. As of the latest data from the EPA, only 27.8% of ferrous metals (those containing iron) were recycled in 2018––and nearly 7.2% of all municipal solid waste landfilled in 2018 was from steel––equivalent to 10.5M tons. The reality is often worse for non-ferrous metals (such as aluminum, copper, nickel) which may only be sorted for recycling after their heavier ferrous counterparts are removed.

These insufficient recycling rates for metals can be attributed to losses during material processing. Current recycling technology and processing capabilities struggle to address the growing complexity of mixed metal products, leading to contaminated and downgraded metal recovery. Scrap processors have historically recovered only certain metal commodities that were perceived to have higher resale value, leaving out other various mixed metals from the sorting process and shipping them overseas. As a result, significant volumes of aluminum, copper, nickel and cobalt are lost from our domestic supply. However, increasing domestic demand in the U.S. is driving up value for these types of materials, and tools like VALIS’s solution help scrap processors understand the monetary value of the metals they are currently selling overseas.

Closed Loop Partners has long understood the complexities of end-of-life commodity markets––we’ve been investing in the space for a decade and recognize that challenges exist at every stage in the value chain––collection, sorting, resale and ultimately recovery into the next life. For large format composite metals––such as automotive, appliances and heavy machinery––collection has rarely been a problem. These products are bulky enough that they typically end up in processing facilities around the country. The challenge is what happens after that.

We invested in VALIS because their software improves the sorting process of mixed metals and allows domestic processors to maximize the resale value of the outputs, keeping more metals in local circulation. By capturing data on commodity prices and input materials and delivering high-value insights on material and processing trends, they help optimize sortation processes to capture the most valuable metals that might otherwise be overlooked. With more optimized and predictable sortation, processors can command higher prices for higher quality outputs.

As the U.S. faces an extreme shortage of critical metals that are required for the renewable energy transition, solutions like this are increasingly important. Copper, nickel, aluminum, graphite and steel among others are seen as critical and are expected to be in short supply. Many companies have now mandated chain-of-custody and fair labor validation of the minerals and metals used within their supply chains. VALIS helps create lower cost, resilient and transparent supply chains for these metals domestically––and focuses on metal recovery from current waste streams rather than incremental extraction. This provides multiple benefits including reducing waste, enhancing local economies and lowering the emissions footprint of the recycled metals.

Overall, VALIS helps recover more pure metals from our existing waste streams, reduces the complexity of the end products that are being sold for the next stage of processing and can help get metals back in circulation faster. They do all of this, while providing the traceability that’s so essential in today’s critical mineral supply chains. VALIS is improving the business case for scrap processors today, while creating new opportunities for greater material recovery from the urban mine. It makes economic sense. It makes emissions sense. And yes, it makes material sense. That’s the circular economy.

About Closed Loop Ventures Group at Closed Loop Partners

Closed Loop Partners is at the forefront of building the circular economy. The company is comprised of three key business segments: its investment arm, Closed Loop Capital Management; its innovation center, the Center for the Circular Economy; and its operating group, Circular Services. Closed Loop Capital Management manages venture capital, buyout private equity and catalytic private credit investment strategies. The firm’s venture capital group, the Closed Loop Ventures Group, has been investing early-stage capital into companies developing breakthrough solutions for the circular economy since 2016. The Closed Loop Ventures Group’s portfolio includes companies developing leading innovations in material science, robotics, agritech, sustainable consumer products and advanced technologies that further the circular economy. Closed Loop Partners is based in New York City and is a registered B Corp. Closedlooppartners.com.

About VALIS Insights

VALIS Insights is building AI-powered software that makes recycling more profitable, material supply chains more sustainable and closes the loop on a circular economy for metal fabrication. With VALIS technology metal recyclers gain visibility into their material quality and make data-driven process decisions to extract more value. Founded in 2022 by experts in metal recycling and data science, VALIS is dedicated to delivering the software and data solutions needed across the recycling value chain to ensure the materials of yesterday are properly recovered for the manufacturing of tomorrow. For more information visit https://www.valisinsights.com/.

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Partners or any company in which Closed Loop Partners or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Information provided reflects Closed Loop Partners’ views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision.

Many Americans Don’t Understand What to Do with Compostable Packaging. Here’s a Solution.

February 20, 2024

As countries and corporations get one year closer to their own deadlines for meeting major climate targets, there are some important pathways to emissions reduction that cannot be ignored. Food waste mitigation is one of them.

Roughly one-third of the world’s food is wasted each year––a loss estimated at $230 billion. Nearly 60% of the uncontrolled methane emissions from municipal landfills are caused by discarded food, highlighting its significant impact on the environment. To address the urgent food waste and climate challenge, demand for organics circularity is rising, and with it, the volume of food-contact compostable packaging––a market poised to grow 16% annually in the U.S. until 2032, 4x faster than traditional plastic packaging.

Certified, food-contact compostable packaging can enable the diversion of food waste from landfill and support a circular economy. If food packaging filled with food scraps is properly recovered and sent to composting facilities, then this food wouldn’t end up emitting greenhouse gases in landfills. The food and packaging would also be converted into nutrient-rich compost. But if certified compostable packaging is not appropriately collected and processed into compost after it’s used, more waste is created.

We often hear that there is a lack of recovery infrastructure for compostable materials. The reality is, U.S. composting infrastructure is in the middle of transitioning from processing just yard waste to accepting more types of inputs, including post-consumer food waste and food-contact compostable packaging. Today, 70% of the 200 full-scale composting facilities that process food waste already accept and process some forms of compostable packaging. Plus, 15 million Americans have access to organics collection, a dramatic 49% increase in access since BioCycle’s last survey in 2021.

For food-contact compostable packaging to be successful in the market today, labeling and design need to be aligned so that consumers throw packaging in the right bin, and composters can easily process these materials. Yet, data shows that some labels confuse consumers, who mistake packaging as compostable when it’s not, or misunderstand where to dispose of that packaging at the end of its use.

Without policies that drive clear, standardized labels and instructions on where compostable packaging needs to go after it’s used, a lot of it ends up in landfills or contaminating recycling streams. Conversely, non-compostable look-alike products and packaging can make their way to compost facilities where they end up contaminating the soil. These look-alikes are the primary contamination challenge in the organics stream.

To address this challenge, the Composting Consortium, led by the Center for the Circular Economy at Closed Loop Partners, and the Biodegradable Products Institute (BPI) embarked on a joint study to test different packaging label and design approaches, and how these inform consumers’ assumptions on what to do with compostable packaging after it’s been used. The findings can inform policies that better support labeling practices and standards for both compostable and non-compostable packaging. In the U.S. today, five states have compostable packaging labeling laws, including Washington, California, Colorado, Minnesota and Maryland. Other states, like Virginia and New Jersey, recently introduced laws that would establish recycling labeling requirements.

Until this study, this information on American consumers had not been publicly available. The Composting Consortium and BPI released the findings in a first-of-its-kind industry report. Here’s a snapshot of what the data reveals:

- Nearly 1/3 of respondents say they would place compostable packaging in the recycling bin

Compostable packaging is not designed to be recycled at a material recovery facility (MRF) and can contaminate the recycling stream if intermixed with fossil fuel-based plastics. Compostable packaging that mistakenly ends up in recycling streams loses a significant portion of its value and creates a contamination challenge that impedes the recovery of valuable recyclable materials. Cross-contamination of the recycling and composting streams is an expensive operational challenge and would pose significant risk to both industries. Brands that have set ambitious sustainable packaging goals are also impacted by inadequate collection and processing of these materials.

Our recommendation: Brands and municipalities should work together on educational campaigns and clear, on-pack messaging.

- Up to 50% of respondents say they would place packaging labeled as “made from plants” in the composting bin

“Made from plants” describes the materials used to make the packaging, not where the package should go at the end of its use. In fact, “made from plants” claims are commonly found on plastic packaging that should be recycled (i.e. PET made from ethanol derived from corn). Our study found that American consumers are especially confused by products and packaging that are not actually compostable yet have green or natural coloring, green tinting, or make claims such as “made from plants” without any context or disclaimer language. These plastic, non-compostable materials are virtually indistinguishable from their compostable counterparts.

Our recommendation: Brands and policymakers should support labeling policies that standardize clear, consistent consumer communications, design and labeling.

Source: Alamy

- Adding a trusted certification logo and larger “compostable” call out increases consumers’ ability to identify packaging as compostable by up to 22%

Our study finds that using at least two to three design elements that call out compostability on food-contact compostable packaging, such as the BPI certification mark, the intentional use of tinting and coloring, and a more prominent “compostable” call out, is most effective for consumer understanding.

Our recommendation: Brands and manufacturers should refer to the Composting Consortium’s latest report and BPI’s Industry Labeling Guidelines for specific examples of packaging design strategies that improve consumer identification, increase recovery of compostable materials and mitigate contamination at facilities.

Coming this month: A new report from the Composting Consortium on contamination rates at different composting facilities! Sign up for a webinar to learn about our findings here!

Without standardized labeling, misleading designs and claims will continue to cause consumer confusion. This research provides insights to brands, manufacturers, consumers, policymakers, municipalities, composters and other stakeholders on effective design and labeling techniques that could improve the diversion of food-contact compostable packaging to the right material stream. While these new findings shed light on the issue, this is just the beginning. As the composting space rapidly evolves, complementary studies will be critical to advancing the recovery of compostable packaging––a critical path to reducing food waste and greenhouse gas emissions.

Learn more about these findings in the latest report from the Composting Consortium and BPI here: https://www.closedlooppartners.com/research/us-consumer-perception-of-compostable-packaging/.

What Brands Need to Know to Increase the Recovery of Compostable Packaging

November 28, 2023

Permitting for composting facilities is complex, but critical. The Composting Consortium breaks it down.

Over the last few years, demand for compostable packaging has grown quickly, as more brands explore alternatives to single-use conventional plastic. Whether in the form of a bowl, fork or a chip bag, compostable packaging is becoming more prevalent each year. At its best, compostable packaging could play an important role in reducing food and packaging waste by helping deliver food scraps within packaging to composting infrastructure, avoiding the greenhouse gases emitted if food were to end up in landfill.

But the reality is that the U.S. composting infrastructure in existence today was predominantly designed to process only yard trimmings––leaves, grass clippings and woody debris––because of a policy trend in the late 80s and early 90s that banned yard waste from landfill in dozens of states. As climate change mitigation and zero-waste goals have emerged, the composting industry is modernizing, diversifying feedstock inputs to include post-consumer food waste and certified compostable packaging. But it is only at the beginning stages of that transition.

The Composting Consortium, a multi-year collaboration across the entire compostable packaging value chain, has been studying composting infrastructure for several years. In the U.S., about 70% of the 200 full-scale composting facilities that process food waste also process some form of compostable packaging. Most of these facilities are located in urban areas. The rest of the over 2,500 composting facilities in the U.S. only process yard waste, meaning most Americans lack convenient options to compost food waste, including food-contact compostable packaging. Creating circular outcomes for compostable packaging hinges on scaling the recovery of food scraps, and brands, packaging manufacturers, industry groups, composters and investors all need to be involved.

What needs to happen so that compostable packaging doesn’t end up as waste?

Several things need to be in place for compostable packaging to operate within a truly circular, waste-free system. Consumer education, supportive policy, and clear and consistent packaging design and labeling all play important roles––and recovery infrastructure is a critical piece to the puzzle.

When envisioning a future system where composting facilities accept not just yard waste, but also food scraps, and the compostable food packaging those scraps often arrive with, the first step is to consider what must be true for facilities to upgrade from yard waste-only composting infrastructure to also recover food.

Only when more food waste is recoverable at composting facilities will it be possible to also see more recovery of food-contact compostable packaging. This infrastructure upgrade is a key steppingstone to reducing packaging waste.

Why do permitting requirements matter?

While there is opportunity to upgrade existing yard trimmings composting facilities to recover food waste––and potentially, also food-contact compostable packaging––it is often difficult to get the necessary permits to do so. In many cases, yard trimmings-only composting facilities are permitted to compost only yard trimmings. To obtain a permit to also compost food waste and make all the necessary upgrades, these facilities would need to go through a lengthy and expensive permitting process.

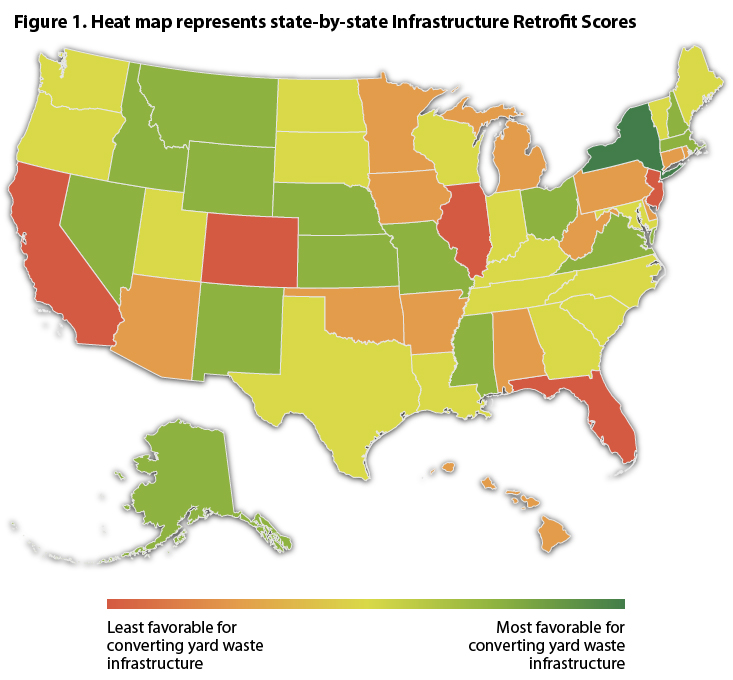

The Composting Consortium, BioCycle and Craig Croker evaluated each of the 50 states’ permitting requirements across five factors to produce a “Composting Infrastructure Retrofit Score” that measures how easy or difficult upgrading existing yard trimmings-only composting facilities would be across different states.

The final Composting Infrastructure Retrofit Score looked across five factors:

- Ease of permitting process: The difficulty of obtaining a permit to compost food waste in a particular state.

- Presence of permitting tier: Whether a state has rules for composting facilities depending on how much and what types of food waste they accept. Some states have stricter rules for facilities that accept large amounts of food waste or food waste that may be contaminated with pathogens.

- Cost to upgrade: The cost of upgrading a yard trimmings-only composting facility to process food waste.

- Time needed to upgrade: The amount of time it takes to upgrade a yard trimmings-only composting facility to process food waste.

- State food waste disposal ban: Whether a state has a ban or mandate that restricts disposal of food waste.

The findings uncovered a patchwork landscape of permitting conditions across the county as shown in BioCycle’s heatmap below. New York state stood out among the 50 states as having a comparatively straightforward process to obtain permits required for infrastructure retrofit, while most states including South Carolina, Rhode Island and California make navigating permitting requirements significantly more costly and time-intensive.

Original Source: BioCycle

In many states, permitting requirements for food waste composting are one of the major factors standing between compostable packaging and the recovery pathways needed to ensure they are a circular alternative to single-use plastic packaging.

What role do brands play in navigating permitting requirements?

CPG brands have a unique opportunity to play a leading role in scaling up a more circular system for food-contact compostable packaging in the U.S.––by investing in recovery solutions for food-contact compostable packaging, advancing consumer education, designing packaging that is compatible with food waste composting infrastructure, and advocating for policies––like extended producer responsibility––that can support the development of food waste composting infrastructure.

To advance the necessary upgrades to composting facilities, brands can be supportive of efforts of composting industry groups like the US Composting Council, who advocates for standardized state regulations for composting. Permitting requirements are a determining factor in creating more opportunities for compostable packaging circularity and navigating them requires the engagement of stakeholders across the value chain.

In 2024 and 2025, the Composting Consortium will continue to connect the dots and work with the compost industry, policymakers, and packaging manufacturers and brands to lower the barriers to scaling food-waste composting infrastructure and unlock value to all stakeholders across the composting value chain. Through this unprecedented collaborative work, the Composting Consortium aims to build a more circular composting system, one that drives values to all stakeholders.

Learn more about the work the Consortium is doing to scale circular outcomes for compostable packaging.

About the Composting Consortium

The Composting Consortium is a multi-year collaboration to pilot industry-wide solutions and build a roadmap for investment in technologies and infrastructure that enable the recovery of compostable food packaging and food scraps. The Composting Consortium is managed by Closed Loop Partners’ Center for the Circular Economy. PepsiCo and the NextGen Consortium are founding partners of the Consortium. Hill’s Pet Nutrition parent company Colgate-Palmolive, Danaher Foundation, Eastman, The Kraft Heinz Company, Mars, Incorporated, and Target Corporation joined as supporting partners, and the Biodegradable Products Institute, the US Composting Council and the U.S. Plastics Pact joined as industry partners. Our advisory partners include 5 Gyres, Foodservice Packaging Institute (FPI), Google, ReFED, Compost Research and Education Foundation (CREF), the Sustainable Packaging Coalition (SPC), TIPA, University College London (UCL), Western Michigan University (WMU), University of Wisconsin-Stevens Point, and World Wildlife Fund (WWF). Learn more about the Consortium at closedlooppartners.com/composting-consortium/

Why We Invested in Found Energy: The Importance of Circular Energy Solutions

November 27, 2023

This blog is part of our “Why We Invested” series, which offers a deep dive into our most recent investments and the growing circularity trends in the space.

At Closed Loop Partners, we focus on investing in the circular economy––advancing solutions that reduce waste through material reduction, alternative materials, reuse and end-of-life solutions like recycling. Through our work, we help reduce the 45% of all emissions derived from the way we make and use products––and where relevant to materials management, we also address the 55% of emissions that are tied to energy production.

Our most recent investment through the Closed Loop Ventures Group in Boston-based company Found Energy embodies this crossover between energy production and materials management. Found Energy upcycles contaminated aluminum into clean hydrogen fuel, while also returning the aluminum to its pre-processing state, creating a fully circular loop for the material. By treating aluminum scrap with a catalyst and then activating it with water, Found Energy creates 1) energy in the form of hydrogen and steam and 2) alumina trihydrate (ATH), a raw material used to manufacture aluminum.

The process unlocks two major benefits:

- Onsite Energy Generation: Any equipment manufacturer, processor or even materials recovery facility can produce their own on-site, clean hydrogen fuel and steam using energy dense aluminum as a means of energy storage. On-site production helps alleviate the challenge of expensive hydrogen transportation and storage.

- Upcycling: Aluminum alloys otherwise destined for downcycling may be reintroduced into the supply chain as alumina trihydrate that can then be processed into virgin-grade aluminum.

Why does aluminum recovery matter?

Aluminum is already one of the most abundantly recycled metals on the planet and can be recycled many times over. More than other classes of recyclables, there is broad consumer participation in aluminum recovery (by recycling cans), and the prevalence of aluminum as a lightweight structural element in manufactured goods (such as automobiles and appliances) means that ample end-of-life aluminum is processed every year. In fact, 75% of all aluminum ever produced is still in use today. Recycled aluminum only takes ~5% of the energy needed to make new aluminum and reduces the need to mine for bauxite––the most common ore needed for aluminum.

However, while recycling rates for aluminum are generally high, they differ substantially by product, alloy and region, ranging from as low as 20% to as high as 80% for some packaging products. We have learned that in the depths of smelters, aluminum recycling is limited to recovery within established alloy classes (meaning two or more metals or a metal with another non-metallic addition). Given that aluminum can be 2x more energy dense than diesel and 5x more energy dense than methanol, there is value in finding opportunities to keep more aluminum in circulation as both a material and energy source.

The main challenge with recovering scrap aluminum is removing tramp elements, which cannot be separated easily by current smelting processes given the high melting temperature of aluminum (660° C). This means contaminated aluminum is often downcycled or ends up in landfills.

Found Energy has discovered a clean energy solution for scrap aluminum, working at the intersection of circular economy principles and the clean energy transition. After building this technology for years during his time at MIT and motivated by his work at NASA, co-founder and CEO Peter Godart brought Found Energy to life in 2022.

Unlike other energy solutions we have seen, Found Energy considered end-of-life from the very beginning of their development process, while using scrap aluminum as a wholly recoverable material source for energy generation plus storage. We fully support the transition to renewable feedstocks for clean energy, while recognizing that the structures required to facilitate clean energy transfers, like solar panels and wind turbines, often utilize extractive or single-use resources that frequently end up in landfill after they are decommissioned. We believe that it is better both economically and ecologically to keep these materials in circulation, and up until recently, had yet to find an energy technology that is inherently circular––inclusive of the materials used in the machinery and the renewable feedstock.

We were impressed with the elegance of a solution that uses a ubiquitous metal as a novel hydrogen source, is highly mobile, and can be distributed. Distributed assets will continue to be a priority in places where heavy materials would otherwise be transported long distances, or where permitting and absence of transmission infrastructure can keep manufacturing operations from scaling up their energy loads as needed.

To create a truly waste-free future for renewable energy, we must support the circularity of materials, alongside clean energy innovation. Reducing carbon through circular processes like material recovery and re-manufacturing is critical to reaching our CO2e mitigation goals and living in an ecosystem that is resilient to further climate shocks. Found Energy is helping pave the path forward.

About Closed Loop Partners

Closed Loop Partners is a leading investment firm advancing the circular economy. The company is comprised of three key business segments: its investment arm, Closed Loop Capital Management; its innovation center, the Center for the Circular Economy; and its operating group, Circular Services. Closed Loop Capital Management manages venture capital, buyout private equity and catalytic private credit investment strategies. The firm’s venture capital group, the Closed Loop Ventures Group, has been investing early-stage capital into companies developing breakthrough solutions for the circular economy since 2016. The Closed Loop Ventures Group’s portfolio includes companies developing leading innovations in material science, robotics, agritech, sustainable consumer products and advanced technologies that further the circular economy. Closed Loop Partners is based in New York City and is a registered B Corp. closedlooppartners.com.

About Found Energy

Found Energy is a Boston-based company building rechargeable aluminum fuel power systems aimed at eliminating carbon emissions from heavy industrial applications ranging from industrial heating (7% of global CO2 emissions) to maritime shipping (3% of global CO2 emissions). Building off technology developed at MIT that enables metallic aluminum to split water, our energy delivery systems safely generate hydrogen and/or industrial heat on-site at >5x the volumetric energy density of liquid hydrogen, >3x that of methanol and ammonia, and >25x that of Li-ion batteries. By integrating storage, transport, and generation into a single package, our technology solves some of the biggest pain points in renewable energy transmission and storage.

Disclaimer:

This publication is for informational purposes only, and nothing contained herein constitutes an offer to sell or a solicitation of an offer to buy any interest in any investment vehicle managed by Closed Loop Capital Management or any company in which Closed Loop Capital Management or its affiliates have invested. An offer or solicitation will be made only through a final private placement memorandum, subscription agreement and other related documents with respect to a particular investment opportunity and will be subject to the terms and conditions contained in such documents, including the qualifications necessary to become an investor. Closed Loop Capital Management does not utilize its website to provide investment or other advice, and nothing contained herein constitutes a comprehensive or complete statement of the matters discussed or the law relating thereto. Information provided reflects Closed Loop Capital Management’s views as of a particular time and are subject to change without notice. You should obtain relevant and specific professional advice before making any investment decision. Certain information on this Website may contain forward-looking statements, which are subject to risks and uncertainties and speak only as of the date on which they are made. The words “believe”, “expect”, “anticipate”, “optimistic”, “intend”, “aim”, “will” or similar expressions are intended to identify forward-looking statements. Closed Loop Capital Management undertakes no obligation to update publicly or revise any forward-looking statements, whether as a result of new information, future developments or otherwise. Past performance is not indicative of future results; no representation is being made that any investment or transaction will or is likely to achieve profits or losses similar to those achieved in the past, or that significant losses will be avoided.

Reuse

Debunking Durability: How Durable Does Reusable Packaging Need to Be?

October 24, 2023

When reuse started regaining popularity in the United States, it was hard to imagine how any version of reuse could be worse for the environment than single-use equivalents. Today, there’s growing awareness of potential unintended consequences of reuse if return rates, and associated packaging use cycles, are not high enough to justify the added durability (and material) that comes with reusable packaging.

With the newest wave of reuse policy discussions and renewed efforts to integrate reuse models into reduction requirements of Extended Producer Responsibility (EPR) bills, there is growing confusion on what defines a “good” reuse system. Although many metrics are cited, use cycles or return rates paint the most robust picture of how well a reuse system is operating in practice. As we build the reuse systems of tomorrow, a universal understanding of such metrics is essential. So, what is a high enough return rate?

The reality of today’s reuse rates

Across different sources, the number of reuses required to offset the added durability and materials needed for reusable packaging (also known as the breakeven point) is said to range from about five to 800 uses. But in today’s reality, reusable packaging is often reused less than five times, based on the results of past and ongoing open-system reuse pilots. For containers to have five uses on average in their lifetime, return rates need to be 80%. For a 90% return rate––which we have yet to see in open systems at scale––containers are used only 10 times on average.

Achieving five to 10 uses is still a dream state for most open-environment reuse systems, yet we see packaging designers choosing and testing packaging materials to withstand dozens, and sometimes hundreds, of uses. Brands and manufacturers designing reusable containers are often reacting to regulations that set up unreasonably high use targets for open-system models. CalRecycle suggests washable as something that lasts 780 cycles. The Choose2Reuse drafted regulation cited a requirement of about 1,000 cycles. These types of requirements force the industry to design packaging for aspirational return rates, making breakeven points even higher.

Why designing for current state matters

To mitigate the environmental impact of reuse, reusable packaging needs to be designed for current return rates. Otherwise, you limit the environmental benefits by potentially generating a higher volume of materials, that are less likely to be recovered.

Additionally, durability will naturally be a function of usage environment; reusables must be appropriately designed for their expected use case. Items made for more closed environments, such as dine-in at a restaurant or for a drink at a venue, may have higher use cycles than open environments, such as takeaway or delivery.

The bottom line: as we transition toward more widespread reuse, we need to design with actual return rates and uses cases in mind. We must also ensure that containers that are not returned for reuse are recycled at their end-of-life (learn more about designing for end-of-life here).

While we work towards building the convenience and incentives needed to increase return rates, we must ask: what’s the least amount of material that we can put in a returnable packaging solution today to make it durable enough to survive five to 10 uses? Will it look sufficiently like a durable reusable to signal returnability? And ultimately, how many cycles does a container need to survive to beat its single-use equivalent? For open reuse systems today, when the answer is less than five or so cycles, the packaging design is going in the right direction.

Reusable packaging is at an important inflection point. New innovations are expanding what is possible, but to ensure that reuse does not generate unintended environmental consequences, reusable packaging needs to be thoughtfully designed with today’s reality in mind. Designing reusable packaging with current return rates, use cases and eventual end-of-life in mind are all critical steps to building a reuse system that truly advances a circular economy and a waste-free future.

Reuse

When Reusable Cups Reach End-of-Life: 5 Tips to Ensure They Don’t Go to Waste

October 18, 2023

We know reuse plays a critical part in reducing foodservice packaging waste. And we’ve seen progress and innovation across all types of packaging and foodservice venues, whether cup share programs, reuse at concerts and events, or even for food delivery services. However, for reuse models to be successful and impactful, they need to check a lot of boxes––they have to fit the lifestyle of customers and align with the reality of retail operations to ensure reusable packaging is sufficiently reused. They also have to be recyclable so that they don’t become waste when they end up somewhere other than the return bin at any point in their lifecycle. Whether a reuse program has a 95 percent (terrific!), 75 percent (needs improvement) or 25 percent (look out!) return rate, designing for recyclability is key, especially as more reusable packaging enters the ecosystem. Appropriate end-of-life management is necessary to maximize the intended environmental benefit that reusable products offer.

Since 2018, the NextGen Consortium has been leading efforts to identify the role reuse can play in addressing foodservice packaging waste, alongside material innovation and recovery [see: Bringing Reusable Packaging Systems to Life: Lessons Learned from Scaling Reusable Cups]. In addition to examining the realities of consumer behavior and retail operations when deploying reuse systems, one critical question we recently investigated is: what happens when a reusable cup ends up in the recycling system?

Reusable foodservice packaging is often designed for durability––both in how long it can be reused and how many times it can be washed––but not always for recyclability. As a result, when reusable cups are decommissioned, or end up anywhere but the reuse bin, they inevitably end up in our waste streams. From NextGen’s consumer research, we know that unless disposal options are convenient, these cups will likely end up as waste. Designing reusable packaging for both consistent reuse and eventual recyclability will help increase recovery opportunities and reduce waste to landfill and the environment.

How do we ensure reusable cups do not become waste when they can no longer be reused or end up in a recycling bin rather than a reuse bin?

Testing is key. There are excellent design guidelines, such as APR’s design for recyclability guidelines, to help suppliers ensure their packaging meets the stated needs of the recycling system today. But reusable cups also need to be tested within the recycling process to see if they can be successfully recovered. There are three critical stages of the recycling process:

- Collection: how recyclable materials are collected in residential or commercial waste streams

- Sortation: how a package will flow at a material recycling facility (MRF)

- Reprocessing: how a package aligns with similar materials to be processed and remanufactured into new materials

In early 2023, the NextGen Consortium collaborated with Van Dyk Technology Center to test how a dozen different reusable polypropylene (PP) cups would sort within a MRF and see if they would end up in the correct material bale, in this case PP.

The test mimicked the flow of a typical MRF, followed APR’s sorting guidance and tested how size, compression, 2D and 3D sortation, and near infrared (NIR) sortation impact how well a cup can be sorted. The results were mixed and provide critical design insights for the companies who are manufacturing and deploying reusable cup formats.

The Results: the good, the bad and the unrecyclable.

When designed with recycling in mind, a reusable PP cup should successfully sort into the correct bale at a MRF. In our tests, the top four best performing cup models were sorted correctly more than 90 percent of the time. The test ran 50 samples of each cup through four separate runs so that each cup model ran through the facility 200 times. The results are no coincidence: successful sortability was driven by specific factors, including color, shape, opacity, thickness and material composition. The highest performing cups were typically opaque, thin and rigid but had some flexibility or bounce, and were all read clearly by the optical sensors of the sortation equipment. Cups that performed poorly, sorting less than 50 percent of the time (or sometimes not at all), often were more translucent than their successful counterparts. Overall, while only four of the cups achieved successful sortation (and a fifth cup was borderline), simple design corrections can improve the fate of the others.

Design Tips: Making recyclability a priority for reusable PP cups.

The Van Dyk sortation test gave a window into what happens to various types of reusable PP cups traveling through a MRF. However, this only assessed one step in the recycling process––sortation––and does not confirm compatibility with reclamation systems nor prove that the cup can be recycled effectively into a new package. Additional testing is needed to confirm assumptions that reusable PP cups are truly circular. For now, reusable foodservice packaging companies and suppliers can design with sortation in mind and improve end-of-life outcomes by considering the following:

- Follow the design guidelines created by APR and other groups: There are many resources available online to help packaging designers/suppliers ensure greater compatibility with the recycling system. For plastic packaging, the APR Design® Guide is a great place to start.

- Avoid all black plastics: While there have been technological advancements to help sort black plastics, most MRFs do not possess that technology. Both opaque and translucent black packaging is problematic and reusable cup manufacturers should design cups with today’s system in mind. If black is absolutely required, use an NIR sortable black colorant. Colorants that have passed APR testing can be found on APR’s website here.

- Not all polypropylene is equal: PP is a wide class of material. PP sorters in the recycling process are designed to detect and separate PP that is common to single-use plastic such as tubs and lids; however, other PP grades may not be as easily identified.It is critical to engage with your cup suppliers and test if needed to confirm compatibility.

- Mono materials (cups made of just one material) are best: A reusable cup that is multi-material (i.e., part plastic, part fiber, part silicone, etc.) is simply not compatible with today’s recycling system. Cups designed to be in a high-volume sharing system should be made of a singular material and avoid too many add-ons. Cups with ridges (i.e., a built-in sleeve) may also impede sortation; however, it does not appear that those design features are overly detrimental.

- Think twice before adding tech: Tracking systems are typically needed to assess the impact of a reuse system and enable traceability, but features such as Radio Frequency Identification (RFID) tags need to be evaluated further for their impact on the recycling system. While an RFID tag is unlikely to hinder a package’s sortability, it might impact whether a material can be reclaimed or recycled. APR’s guidance lists RFID tags as “detrimental,” and the NextGen team is investigating the impact this technology has on the system.

When in doubt, TEST.

Despite widely available design guidance, reusable packaging that is not compatible with today’s recycling system continues to be manufactured. The conversation needs to be more nuanced and shift from only discussing designing for durability and the number of washes a package can withstand, to the realities of how the packaging will actually be used and travel through a system. Most reusable wares in an open system would be lucky to hit 40 reuses (which would assume a >95% return rate)! Sortation and recovery testing can help provide reusable foodservice packaging companies with additional peace of mind and ensure that their packaging has a better chance of staying out of landfill.

The NextGen team looks forward to continuing this journey to study and test optimal conditions for reusable packaging to succeed and achieve a positive environmental impact within a circular economy.